In recent years, the demand for China Slip On Flanges in industrial applications has experienced remarkable growth, driven by an expanding manufacturing sector and increasing infrastructure projects. According to a report by the China Industrial Flange Association, the production of flanges in China is projected to reach approximately 1.2 million tons by 2025, reflecting a compound annual growth rate (CAGR) of 5.4% from 2020. This surge highlights the critical role that China Slip On Flanges play in ensuring safety and efficiency in piping systems across various industries, including oil and gas, chemical processing, and construction.

Industry expert Dr. Li Wei, a leading authority on flange designs, states, "The evolution of China Slip On Flanges is pivotal in addressing both standardization and customization needs in modern industrial applications." His insights underscore the importance of these components in enhancing the reliability of connections and facilitating maintenance procedures. As we look toward 2025, understanding the top contenders in the market will equip industrial professionals with the knowledge necessary to make informed choices, ensuring optimal performance in their operations. This article will delve into the top 10 selections for China Slip On Flanges, focusing on their attributes, applications, and market relevance, setting the stage for a comprehensive overview of this essential industry segment.

As we approach 2025, the industrial sector is witnessing substantial innovations in the design and application of slip-on flanges. These crucial components, used in piping systems for optimal flow and pressure management, are now being influenced by advancements in materials technology and manufacturing processes. According to a recent industry report by MarketsandMarkets, the global flanges market is projected to reach USD 14.2 billion by 2025, driven largely by expanding industrial activities and the demand for efficient pipeline systems.

One of the top trends influencing slip-on flanges is the growing emphasis on sustainability and eco-friendly materials. Manufacturers are increasingly focusing on low-carbon alternatives, which align with global efforts to reduce carbon footprints. Furthermore, smart technologies are becoming integral to flange design and implementation, enhancing operational efficiency and maintenance strategies. A survey conducted by Grand View Research indicated that the adoption of smart flanges is expected to boost operational productivity in industrial applications by up to 40% by 2025. With these trends, the industry is not only set to improve performance and reliability but also to meet the rising expectations for environmental responsibility in manufacturing practices.

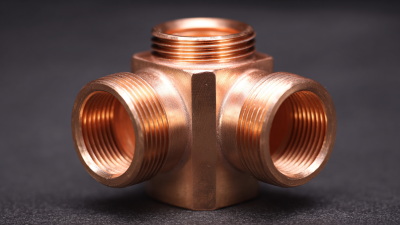

Slip-on flanges are widely used in various industrial applications due to their ease of installation and

cost-effectiveness. The choice of materials for these flanges plays a critical role in their performance

and longevity. Commonly used materials include carbon steel,

stainless steel, and alloy steel,

each offering a unique set of benefits. For instance, according to a 2022 market analysis

by Global Industry Analysts, stainless steel flanges are favored for their

corrosion resistance and strength, making them ideal for volatile environments such as chemical processing plants.

When selecting materials for slip-on flange manufacturing, it’s essential to consider the application's

specific requirements. Carbon steel flanges are typically

used in low-pressure systems, while stainless steel variants

are recommended for applications requiring hygiene and cleanliness, such as food and beverage industries.

A recent report from the Institute of Materials shows that the performance longevity of stainless steel

flanges can exceed 25 years when properly maintained, compared to

10-15 years for carbon steel under the same conditions.

Tips: Always ensure correct material selection based on environmental

conditions and stress factors to maximize the lifespan of your slip-on flanges. Regular inspection and

maintenance can also significantly enhance performance and reliability. Moreover, investing in high-quality

flanges from reputable manufacturers can provide long-term cost savings and improved operational efficiency.

In the expanding landscape of industrial applications,

slip-on flanges have gained notable traction due to their ease of installation and effectiveness in various piping systems.

This 2025 overview explores the leading manufacturers in China, who have become significant players in the global market.

Companies such as Zhejiang Yuhuan Wenzhou and Hebei Woke are known for their superior quality and innovative designs,

catering to the increasing demand for reliable flange solutions across diverse sectors.

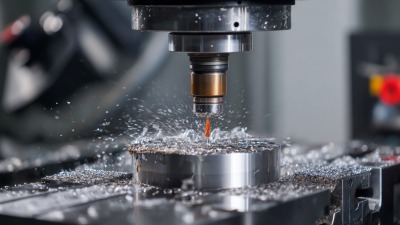

Chinese manufacturers emphasize investing in advanced technology and quality control,

ensuring that their slip-on flanges meet both domestic and international standards.

The use of high-grade materials and adherence to rigorous production processes have positioned these companies

at the forefront of the industry. In addition to providing standard specifications,

they also offer customizable options to meet specific client needs, further enhancing their competitive edge in the global market.

As industries evolve, the contribution of these leading manufacturers in shaping the future of slip-on flanges remains pivotal.

As we look ahead to 2025, the landscape of slip on flanges in industrial applications is poised for exciting innovations in design. Recent industry reports indicate that the global flange market is expected to reach approximately $14 billion by 2025, with slip on flanges representing a significant portion of this growth. These flanges are praised for their ease of installation and effectiveness in high-pressure environments, making them increasingly preferable across industries such as oil and gas, power generation, and chemical processing.

One key trend in the design of slip on flanges is the integration of advanced materials that enhance durability and resistance to extreme temperatures and corrosion. The introduction of composite materials and specialized coatings is anticipated to improve lifespan and performance, reducing maintenance costs for operators. Additionally, the incorporation of digital technologies, such as smart sensors in flange designs, will allow for real-time monitoring of flange integrity, thereby increasing safety and efficiency.

**Tips:** When selecting slip on flanges for future projects, consider the specific material requirements and pressure ratings that suit your industrial applications. It's also wise to stay abreast of new technologies in flange design, as these innovations can significantly impact operational efficiency and safety standards in your facility.

This chart illustrates the projected market share of the top 10 slip on flanges in China for industrial applications in 2025. The values are based on estimated production and demand trends in the industrial sector, highlighting the innovations and improvements in design expected for these components.

In the burgeoning industrial sector of China, the demand for Slip On Flanges is witnessing significant growth. As industries ramp up production and expand operations, the requirement for reliable piping components has surged. This trend is primarily driven by the manufacturing, oil and gas, and construction industries, where Slip On Flanges are essential for creating robust connections between pipes. With China being a global leader in industrial output, the supply of these flanges must keep pace with the increasing demand to ensure consistent operational efficiency.

When navigating the market dynamics, it’s essential to consider some practical tips. First, businesses should focus on building strong relationships with reliable suppliers to mitigate potential supply chain disruptions. Establishing long-term partnerships can help secure better pricing and availability. Second, companies should stay updated on technological advancements in flange manufacturing to ensure they are not only compliant with industry standards but also at the forefront of innovation.

Moreover, understanding regional market trends is crucial. Different provinces may exhibit varying needs based on local industrial activities. Regular market analysis can aid businesses in predicting shifts in demand and adjusting their procurement strategies accordingly. Embracing a proactive approach will ultimately lead to a more sustainable and profitable operation in the Slip On Flange market.