The demand for Chromium Carbide Plate is surging across various industries. According to a recent report by MarketsandMarkets, the global market for wear-resistant materials is expected to grow significantly, reaching $13.2 billion by 2026. This growth reflects the increasing focus on durability and performance in harsh environments.

Dr. Helen Anderson, a leading expert in wear-resistant materials, emphasizes the importance of innovation in this space. "Adaptation and improvement of Chromium Carbide Plates are vital for meeting the evolving demands of modern applications," she asserts. This highlights the ongoing need for improvements in efficiency and lifespan, particularly in mining and construction sectors.

As manufacturers adopt advanced technology, the potential applications for Chromium Carbide Plate continue to expand. Yet, challenges remain in sustainability and production costs. It's essential to balance performance with environmental impact. Moving forward, the industry must address these concerns while fostering innovation to fulfill growing market expectations.

The year 2026 is set to usher in new and exciting applications for chromium carbide plates. These materials are widely recognized for their high hardness and excellent wear resistance. In mining and construction, they are now used in more innovative ways. Conveyor belts and chutes fitted with chromium carbide plates have shown longer lifespans, reducing downtime and costs.

Additionally, industries are exploring the use of chromium carbide in more unconventional applications. For instance, its incorporation into protective gear is gaining traction. Workers in harsh environments can benefit from lightweight, protective fabrics reinforced with chromium carbide components. This innovation could enhance safety while maintaining comfort.

However, the transition to these advanced applications is not without challenges. Manufacturers must consider cost implications and production adjustments. Quality control measures will need to evolve as new techniques emerge. It’s essential to address potential limitations while exploring the full capabilities of chromium carbide plates. Engaging in these reflections can lead to better implementation strategies.

This chart illustrates the expected growth in various applications of chromium carbide plates by 2026. The data reflects the anticipated demand across several key industries.

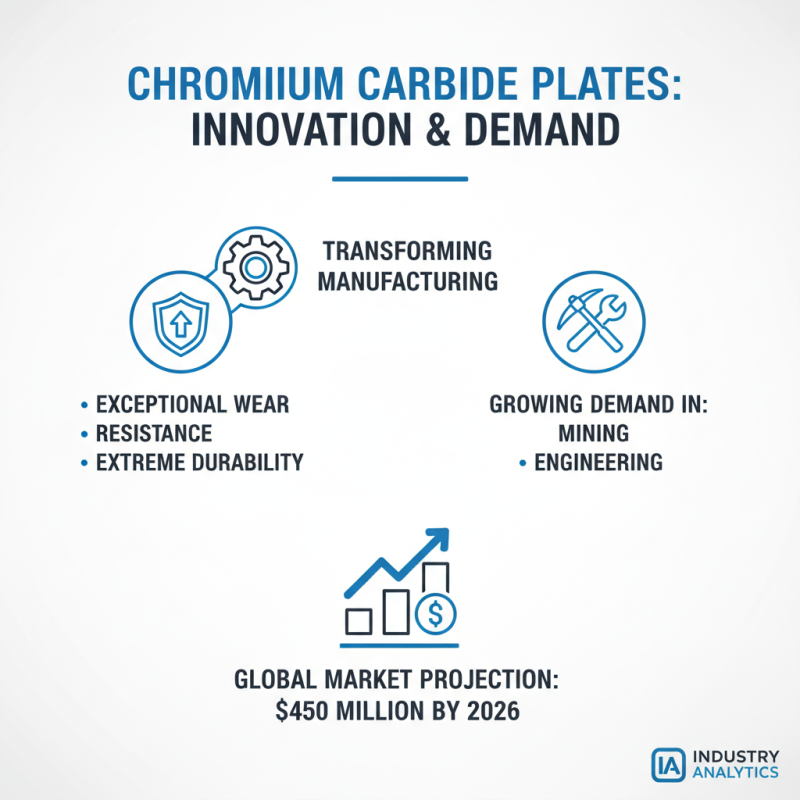

Innovative manufacturing techniques for chromium carbide plates are transforming the industry. These plates are known for their exceptional wear resistance and durability. Recent reports show a growing demand for chromium carbide plates, particularly in mining and engineering. The global market is expected to reach $450 million by 2026.

Additive manufacturing has emerged as a game changer. This method allows for more complex shapes and reduced waste. However, the process can be slow and expensive. Industry professionals are still exploring ways to optimize speed while maintaining quality.

Another promising technique is laser cladding. This method enhances the surface properties of existing materials. It can significantly extend the life of components used in harsh environments. Yet, it requires skilled technicians and precise equipment. Training programs need to be developed to tackle this skill gap. Balancing innovation with practical application remains a challenge for many manufacturers.

Chromium carbide materials are rapidly evolving. These materials excel in performance and durability. Recent industry reports indicate that chromium carbide plates can withstand extreme wear and tear. They are critical in mining, construction, and industrial applications. The increasing demand for high-performance materials drives innovation in this space.

Research highlights improvements in the production processes of chromium carbide. New techniques enhance wear resistance while reducing production costs. For instance, advances in thermal spray technology are noteworthy. Studies show that these innovations can improve the lifespan of components by up to 30%. The growing use of chromium carbide in high-temperature applications is particularly telling.

However, challenges remain. Quality control during manufacturing can be an issue. Variability in material properties sometimes leads to inconsistent performance. Further research is needed to address these gaps. Understanding the long-term performance of chromium carbide in various environments is vital. Continuous innovation will push the boundaries of what chromium carbide can achieve.

The demand for chromium carbide plates is rising steadily across various industries. A recent market analysis has revealed that the global market for these plates is expected to reach approximately $1.1 billion by 2026. This growth is largely driven by the increasing need for wear-resistant materials in sectors such as mining, construction, and manufacturing.

Many manufacturers are investing in advanced technologies to enhance the performance of chromium carbide plates. For instance, novel coating methods and alloy compositions are being developed to improve their durability. Research suggests that wear-resistant solutions can reduce operational costs by up to 30%. However, the production process can be complex and sometimes costly. Balancing innovation with affordability remains a challenge.

Moreover, environmental concerns are prompting companies to reassess their sourcing practices. Ethical sourcing of raw materials is crucial. Some organizations struggle to meet sustainability standards while remaining competitive. The ongoing shift towards eco-friendly materials may reshape product development in the coming years. Keeping up with these trends requires agility and foresight. As we approach 2026, the chromium carbide plate market will continue to evolve, influenced by both innovation and environmental responsibility.

| Application Area | Innovation Type | Market Demand (2026) | Growth Rate (%) | Key Benefits |

|---|---|---|---|---|

| Mining and Mineral Processing | Enhanced Wear Resistance | $150 Million | 10% | Increased equipment lifespan |

| Construction | Corrosion Resistance Coatings | $120 Million | 8% | Durability and maintenance cost reduction |

| Oil and Gas | Smart Coatings Technology | $100 Million | 12% | Enhanced efficiency and safety |

| Automotive | New Alloy Compositions | $80 Million | 15% | Improved performance under stress |

| Aerospace | Lightweight Protective Films | $50 Million | 9% | Weight reduction and fuel efficiency |

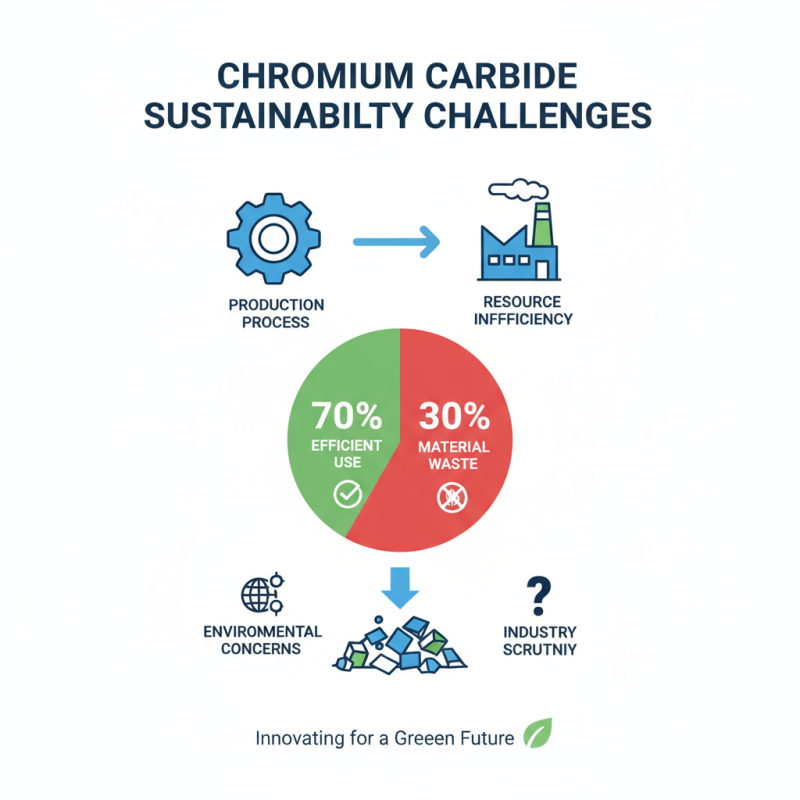

The sustainability of chromium carbide innovations presents a complex challenge. Recent studies show that the production of chromium carbide can lead to significant waste. Approximately 30% of the raw materials may end up as scrap, raising concerns about resource efficiency. This inefficiency invites scrutiny on environmental practices within the industry.

Moreover, the carbon footprint of chromium carbide manufacturing has drawn attention. Reports indicate that greenhouse gas emissions can reach up to 1.8 tons per ton of product. As companies pursue greener alternatives, exploring recycling methods and eco-friendly processes becomes crucial. Innovations in reducing emissions, such as using renewable energy sources, are essential.

There are promising advancements in chromium carbide applications. However, the energy-intensive nature of production needs addressing. Transitioning to cleaner technologies could enhance sustainability. Striking a balance between performance and environmental impact remains a pressing issue. A critical examination of industry practices will help pave the way for a greener future in chromium carbide applications.