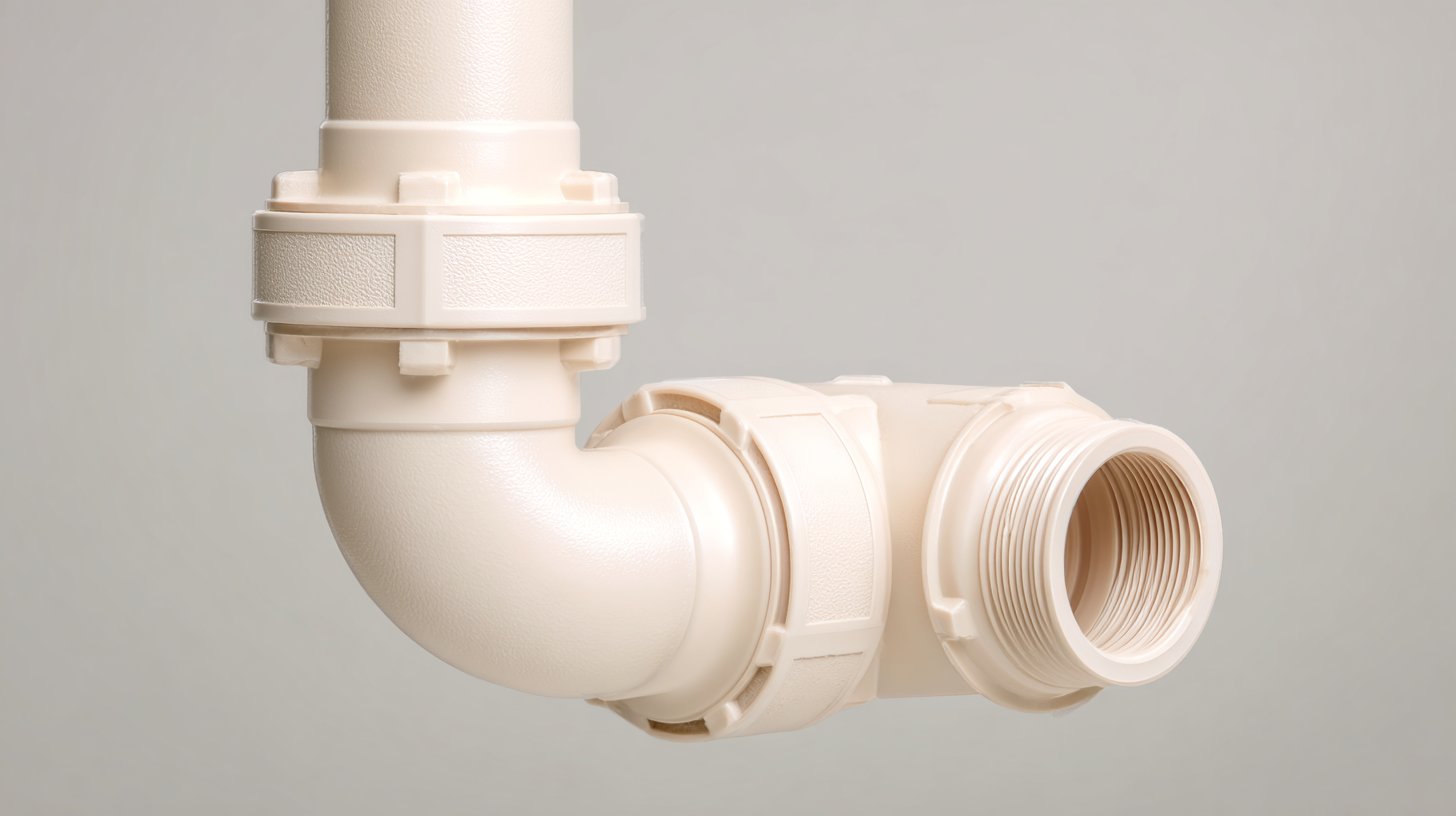

In modern plumbing systems, the choice of materials and fittings plays a crucial role in ensuring durability, efficiency, and safety. One such innovative solution is the CPVC threaded elbow, a versatile component that stands out for its ability to facilitate smooth directional changes in piping installations. Understanding the benefits and applications of CPVC threaded elbows is essential for both professional plumbers and DIY enthusiasts alike. These fittings not only provide excellent resistance to corrosion and scaling but also boast a lightweight design, making them easier to handle during installation. Additionally, CPVC’s high-temperature tolerance further enhances the performance of plumbing systems in various environments. This article aims to delve into the practical advantages of using CPVC threaded elbows, exploring their applications, installation techniques, and best practices to help you make informed decisions for your plumbing projects.

CPVC threaded elbows have become increasingly popular in modern plumbing systems due to their efficiency, durability, and resistance to corrosion. According to the Plastics Pipe Institute (PPI), CPVC pipes and fittings can maintain their integrity under prolonged exposure to corrosive substances, leading to reduced maintenance costs over time. This makes CPVC an excellent choice for residential and commercial plumbing applications where durability is crucial.

One of the primary benefits of using CPVC threaded elbows is their ability to facilitate efficient plumbing layouts. Their lightweight nature combined with excellent flow characteristics can reduce energy usage by up to 20% compared to traditional metal fittings. Additionally, because CPVC does not corrode, users can expect fewer leaks, contributing to sustainable water management and lower water bills.

Tips: When installing CPVC threaded elbows, ensure all connections are properly glued and the pipes are cut squarely to prevent leaks. Moreover, always check local plumbing codes to verify that CPVC is an approved material for your plumbing system, as regulations can vary by region. Regularly inspect your plumbing systems for any signs of wear to maintain optimal performance.

CPVC threaded elbows are increasingly recognized for their versatility and durability in both residential and commercial plumbing systems. These fittings facilitate smooth changes in pipe direction, making them essential in various plumbing layouts. Their resistance to corrosion and ability to withstand high temperatures make them an ideal choice for hot and cold water applications. Recent developments, such as the establishment of large CPVC resin facilities, signify a growing demand for these materials in the construction industry, ensuring that they are readily available for various plumbing needs.

Tips: When selecting CPVC threaded elbows for your plumbing project, consider factors like the pressure ratings and compatibility with existing piping systems. Always ensure that your components are certified and meet the required standards for safety and performance. This diligence will help prevent future plumbing issues and ensure a reliable system.

Moreover, as the market for CPVC products continues to expand, the innovations in manufacturing processes contribute to more efficient and sustainable options. The collaboration of major manufacturers points to an industry that is rapidly evolving, providing better solutions for plumbing infrastructures. Choosing CPVC threaded elbows not only enhances efficiency but also aligns with modern sustainability goals.

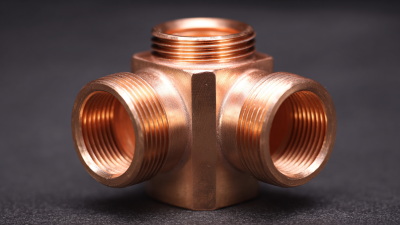

CPVC (Chlorinated Polyvinyl Chloride) and traditional plumbing materials like copper and galvanized steel have distinct advantages that are increasingly influencing modern plumbing systems.

The CPVC market is witnessing substantial growth, driven by its resistance to corrosion, low thermal conductivity, and ease of installation. According to industry reports, the global PVC pipe market is projected to reach

$75 billion by 2027, with CPVC holding a significant share due to its superior performance in high-temperature applications.

In a comparative analysis, CPVC demonstrates clear benefits over traditional materials. For instance, CPVC fittings, such as threaded elbows, offer excellent chemical resistance and can handle higher pressure ratings, making them suitable for a variety of plumbing solutions.

Traditional materials often succumb to rust and scaling, leading to reduced efficiency and increased maintenance costs. It is estimated that adopting CPVC in plumbing installations can reduce material and labor costs by up to

30%, a substantial saving for both residential and commercial projects.

Tips: When considering plumbing solutions, evaluate the long-term benefits of CPVC over traditional materials. Its lightweight nature also allows for easier handling and faster installation, which can further decrease project timelines.

Additionally, ensure you choose fittings that comply with relevant plumbing codes to guarantee safety and durability in your system.

When it comes to installing CPVC threaded elbows in modern plumbing systems, proper techniques can significantly enhance their longevity and performance. Begin by ensuring all surfaces are clean and free from debris. Use a good-quality thread sealant or Teflon tape to prevent leaks, making sure to wrap the tape around the threads in a clockwise direction. Tighten the elbows by hand first, and then use a wrench for extra torque, but avoid overtightening to prevent cracking.

Maintenance of CPVC threaded elbows is straightforward but crucial. Regularly inspect the joints for any signs of leaks or wear. If you notice any issues early on, it's advisable to disassemble the joint, clean the threads, and reapply thread sealant before reassembling. Additionally, avoid exposing CPVC materials to extreme temperatures, as it can lead to deformation. Keeping your plumbing system in check helps ensure it operates smoothly and efficiently, minimizing unexpected repairs.

The rising emphasis on sustainability in modern plumbing systems has brought CPVC (Chlorinated Polyvinyl Chloride) products to the forefront of industry innovations. According to a report by the Plastics pipe Institute, CPVC piping can reduce energy consumption in the transportation of hot water by up to 50%, compared to traditional metal pipes. As plumbing systems increasingly integrate eco-friendly materials, CPVC threaded elbows serve as a key component, enabling efficient water flow while minimizing waste.

Moreover, the durability of CPVC products contributes to their sustainability credentials. A study conducted by the National Association of Home Builders indicates that CPVC has a life expectancy of over 50 years, significantly reducing the need for repairs and replacements. This longevity not only conserves resources but also supports green building initiatives by meeting the leadership standards set forth in energy-efficient building codes. In the shift towards more sustainable plumbing solutions, CPVC's lightweight properties and resistance to corrosion further enhance its appeal, promising a significant reduction in the overall environmental impact of water management systems in the years to come.