In heavy industry, the importance of durable materials cannot be overstated. One such critical component is the Wear Resistant Plate. These plates are engineered to withstand harsh conditions. They provide protection against significant wear and tear caused by abrasives. Their robust design is essential in environments like mining, construction, and manufacturing.

Wear Resistant Plates offer several benefits that enhance operational efficiency. For instance, they reduce maintenance costs and downtime. Machinery runs smoother and lasts longer. In an industry where every minute counts, this is invaluable. Workers can focus on their tasks instead of repairs. However, it's vital to choose the right type based on specific needs.

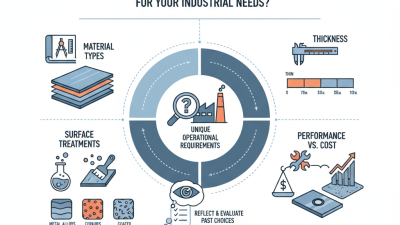

Despite their advantages, there can be challenges. Misapplication of Wear Resistant Plates can lead to issues. Choosing the wrong thickness or material may increase expenses. It’s essential to assess requirements carefully. These decisions can affect productivity and safety. Thus, understanding the role of Wear Resistant Plates is crucial for industry leaders.

Wear resistant plates play a crucial role in heavy industry. Their benefits significantly impact operational efficiency and cost savings. According to recent industry reports, wear resistant materials can extend the lifespan of equipment by up to 50%. This leads to reduced downtime and lower maintenance costs. Industries such as mining, construction, and manufacturing greatly depend on these plates.

In mining operations, for instance, wear resistant plates protect equipment from abrasion caused by materials like gravel and ore. These plates withstand harsh conditions, offering durability and performance. A study highlighted that using wear resistant plates in trucks and conveyors reduces wear-related failures by 30%. This improves productivity by ensuring consistent operation.

However, not all applications may suit wear resistant plates perfectly. Factors like temperature and material composition can affect their performance. For example, extreme temperatures can lead to brittleness in some plates. This requires careful selection based on specific operational conditions. Companies must evaluate the trade-offs involved in using wear resistant materials versus their limitations to achieve optimal results.

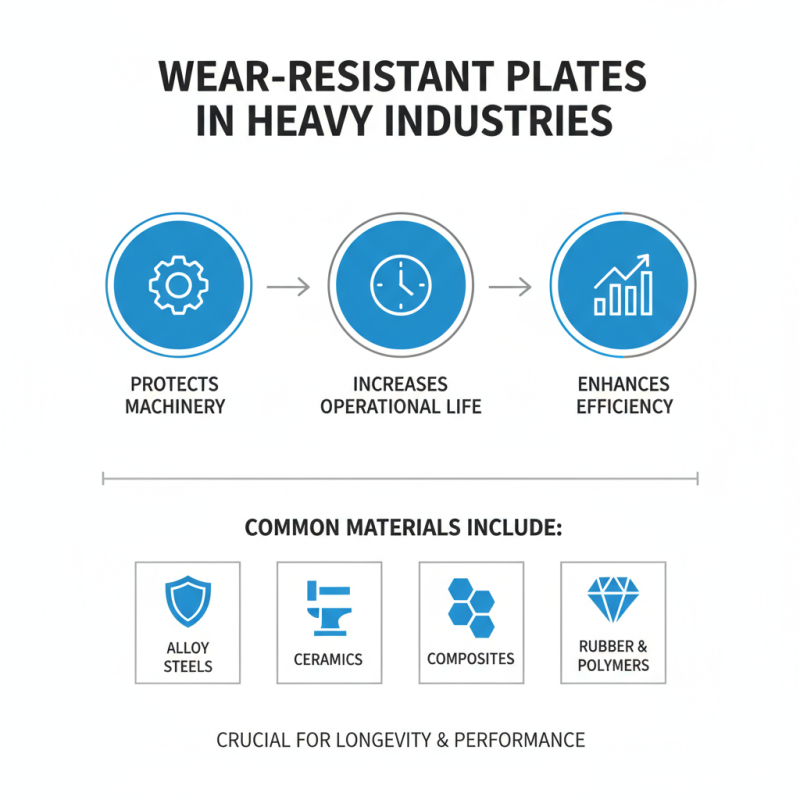

Wear-resistant plates are crucial in heavy industries. These plates protect machinery from wear and tear. They significantly enhance operational life and efficiency. Various materials are used to make these plates.

High-carbon steel is one popular option. It offers excellent wear resistance. Reports indicate that high-carbon steel can last over three times longer than standard steel in abrasive environments. Another common material is alloy steel. It combines hardness and toughness, making it suitable for heavy-duty applications. Ceramic composites are also gaining popularity. They provide outstanding wear resistance and can withstand extreme temperatures.

Tips: Always consider the working environment when selecting materials. Analyze factors like temperature, impact, and abrasion levels.

Rubber-based wear plates are an interesting alternative. They can absorb vibrations and reduce noise. However, they may not be as durable as metal options. It’s essential to balance durability with application needs. Testing different materials on specific equipment can lead to better decisions.

Wear resistant plates offer significant advantages in heavy industry. These plates are designed to withstand abrasion, impact, and wear over time. This durability extends the lifespan of machinery and infrastructure. In operations where equipment frequently encounters harsh conditions, using wear resistant plates reduces maintenance costs. A simple machinery breakdown can halt production for hours. This impact can ripple through the supply chain.

The versatility of wear resistant plates enhances their appeal. They can be tailored for various applications, from mining to construction. In mining, these plates protect vital machinery from rock and debris. Construction sites benefit from their resilience against heavy loads. However, some may overlook the installation process. Poor installation leads to premature wear and failure. Investing in quality installation ensures the plates perform as intended.

Users should also be aware of weight considerations. Heavier plates can provide better protection but may complicate transportation and installation. Striking the right balance is crucial. The goal is to maximize performance without incurring unnecessary costs. Reflecting on these factors helps industries optimize efficiency. Adopting wear resistant plates is a wise decision. However, being mindful of practical challenges is equally important.

Wear resistant plates play a critical role in heavy industry. Their applications are vast across various machinery. Mining, construction, and steel manufacturing heavily rely on these plates. In fact, reports show that about 60% of wear-related failures in heavy machinery can be attributed to inadequate protective materials.

In mining, wear resistant plates protect equipment from abrasive materials. Shovels, draglines, and crushers encounter extreme stress. Their components face cracking and wear due to harsh conditions. Using high-quality wear resistant plates can extend machinery life by up to 30%. However, there’s a challenge: not all industries understand the importance of proper maintenance.

Construction sites also benefit from these plates. Earthmovers and excavators deal with dirt, rocks, and debris. Plates ensure these machines perform efficiently. According to industry estimates, machinery downtime can cost thousands daily. It’s imperative that operators prioritize using the right protective materials. Nonetheless, companies sometimes overlook this aspect, leading to unexpected repairs and losses. These issues often highlight a gap in awareness regarding wear protection strategies.

Maintaining wear-resistant plates is crucial for heavy industry applications. Regular inspections help identify early signs of wear. This proactive approach prevents unexpected failures. Operators should look for surface degradation, cracks, and discoloration. Any of these may indicate that the plate is losing its integrity.

Cleaning is essential for longevity. Dust and debris can speed up wear. Use suitable cleaning agents that do not damage the plate's surface. After cleaning, inspect for deeper issues. Protective coatings can further enhance durability. However, it's important to apply these correctly. Overapplication can lead to chipping or peeling, which compromises efficiency.

Training staff on proper handling is critical. Even minor accidents can lead to significant wear. Encourage a culture of awareness regarding plate maintenance. This includes following best practices for installation and removal. Sometimes, despite best efforts, plates wear down faster than expected. This requires a reassessment of material choices and working conditions. Flexibility and adaptation to changing environments are key in ensuring optimal performance.