In the rapidly evolving landscape of manufacturing, 2025 is projected to be a pivotal year for the integration of advanced components designed for efficiency and durability. One such component gaining significant traction is the Chinese Threaded Flange, which has been recognized for its ability to enhance the reliability of piping systems. According to a recent report by the Global Flange Market Research Institute, the market for flanges, including the Chinese Threaded Flange, is expected to grow by 15% annually as industries seek more effective solutions to handle high-pressure environments.

Industry expert Dr. Lin Wei, a leading authority on flange technology, states, "The adoption of Chinese Threaded Flanges in construction and manufacturing sectors is reshaping how we approach fluid and gas containment solutions." This sentiment reflects the broader manufacturing trends that emphasize innovation and material efficiency. As manufacturers increasingly prioritize sustainability and cost-effectiveness, the versatility and robust design of Chinese Threaded Flanges will likely position them as essential components across multiple sectors.

In this introduction to the benefits of Chinese Threaded Flange, we will explore how its design and function meet the demands of modern manufacturing practices, ultimately driving industry standards higher and fostering a more adaptable supply chain. As we delve into this topic, the operational advantages offered by these flanges will become increasingly apparent, underscoring their significance in shaping the future of industrial manufacturing.

Chinese threaded flanges have gained significant attention in the manufacturing sector due to their unique design and functional advantages. These flanges are characterized by their internal threads, which allow for secure connections to pipes and fittings, enhancing the overall integrity of various systems. In a world where precision and reliability are paramount, these components stand out as essential elements in the construction of pressure vessels, chemical reactors, and piping systems.

One of the notable benefits of Chinese threaded flanges is their ability to simplify assembly processes. By allowing for bolted connections without the need for welding, these flanges can be easily installed and maintained, reducing labor costs and downtime during inspections. This ease of use makes them ideal for manufacturers looking to optimize their production efficiency while maintaining high safety standards.

Tips: When selecting threaded flanges for your projects, consider the material compatibility with the intended application to ensure durability and minimize corrosion. Additionally, always verify the pressure rating of the flanges to prevent failures under extreme conditions. Proper installation techniques are crucial; utilizing the right tools and following manufacturer specifications can significantly enhance the longevity and performance of these critical components.

In the rapidly evolving world of manufacturing, the use of Chinese threaded flanges has become increasingly prominent due to their numerous advantages. A 2023 industry report highlights that threaded flanges can enhance assembly efficiency by up to 30%, which is crucial for manufacturers aiming to streamline operations. The ability to secure joints without welding simplifies installation processes, ultimately leading to reduced labor costs and shorter project timelines. As industries strive to adopt more efficient practices, the demand for easy-to-install components like threaded flanges has surged.

Moreover, the durability and reliability of Chinese threaded flanges play a crucial role in modern industrial applications. According to a study by the International Society for Material Engineering, components that utilize threaded flanges exhibit a failure rate reduction of approximately 15% compared to those using traditional flanging methods. This improvement in joint integrity is essential for industries such as oil and gas, where safe and reliable connections are non-negotiable. As manufacturers become more focused on quality and safety, the advantages offered by Chinese threaded flanges are expected to drive their adoption in the coming years, propelling them to the forefront of industry best practices.

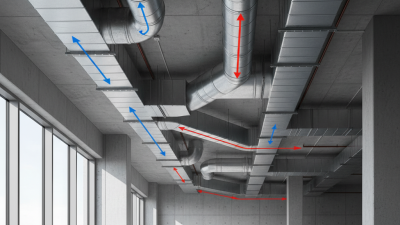

As we look ahead to the manufacturing landscape in 2025, it is essential to consider the evolving role of threaded flanges, which have become increasingly important due to advancements in technology and changes in production methodologies. The integration of smart manufacturing techniques and automation is prompting manufacturers to adopt components that not only enhance efficiency but also ensure reliability.

The Chinese threaded flange, known for its high precision and adaptability, aligns well with these trends, making it a popular choice in modern manufacturing setups.

The impact of these 2025 manufacturing trends on the usage of threaded flanges is noteworthy. With a shift towards sustainable practices and the circular economy, manufacturers are seeking components that minimize waste and maximize functionality. Chinese threaded flanges, characterized by their robust design and ease of installation, contribute to these goals by reducing downtime during assembly and maintenance. Furthermore, as industries increasingly prioritize quality and cost-effectiveness, the superior engineering of these flanges offers a competitive advantage, allowing manufacturers to streamline their operations while adhering to strict quality standards.

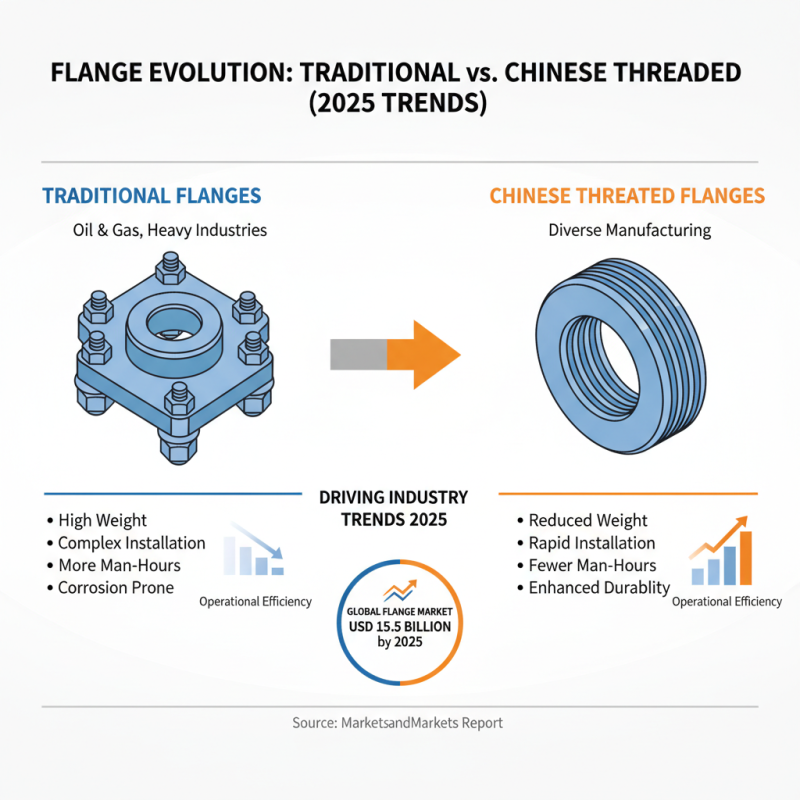

In the evolving landscape of manufacturing, a comparative analysis between traditional flanges and Chinese threaded flanges reveals significant advantages that are driving industry trends in 2025. Traditional flanges, predominantly used in industries such as oil and gas, suffer from drawbacks related to weight and installation complexity. According to a report by MarketsandMarkets, the global flange market is projected to reach USD 15.5 billion by 2025, indicating a growing demand for innovative solutions that enhance operational efficiency.

Chinese threaded flanges, on the other hand, offer numerous benefits, including reduced weight and simplified installation processes. Industry studies suggest that the adoption of threaded designs can lower assembly time by up to 30%, thereby improving overall productivity. Moreover, the precision manufacturing techniques employed in the production of these flanges ensure a high degree of reliability, which is crucial for applications requiring stringent safety standards. As manufacturers increasingly seek to optimize their supply chains, the lower production costs associated with Chinese threaded flanges present a compelling case for their adoption, supported by a shift towards lean manufacturing practices that prioritize cost-effectiveness without compromising quality.

The design and manufacturing of threaded flanges are evolving rapidly as industries seek more efficient and reliable components. In 2025, we can expect significant innovations that focus on enhancing durability, reducing production costs, and improving installation processes. Emerging technologies, such as advanced materials and 3D printing, will play a pivotal role in the development of more resilient threaded flanges. These innovations not only ensure better performance under varying pressures and temperatures but also open new avenues for customization based on specific application requirements.

Tips: When selecting threaded flanges, consider the operating environment and the materials used in the flange construction. This will ensure optimal performance and longevity. Additionally, staying updated with the latest manufacturing trends, such as those involving sustainable practices and automation, can help manufacturers make informed decisions that contribute to overall efficiency.

As we look toward the future, the integration of smart technology into threaded flange designs seems promising. Features like real-time monitoring sensors could provide valuable data on the functioning of flanged connections, alerting users to any potential issues before they escalate. This proactive approach could lead to significant cost savings and enhance safety standards across various industries that rely on threaded flanges for their operations.