In the fast-evolving landscape of construction materials, the choice of components can significantly impact project success. Chinese Threaded Flanges have gained a reputation for their quality and versatility. Industry expert Dr. Li Wei, a prominent figure in flange technology, notes, “Selecting the right threaded flange can make or break project integrity.”

The demand for robust and reliable fittings continues to rise. Chinese manufacturers have stepped up to offer a variety of options tailored to diverse applications. However, navigating these choices requires insight and careful consideration. While many products boast high performance, some may fall short of expectations.

Moreover, the nuances of specifications and standards can lead to misunderstandings. Not every threaded flange is created equal. Different grades and materials can affect durability and safety. Ensuring that you choose the right Chinese Threaded Flange involves thorough research and a willingness to learn from past oversights. Aiming for the best option is essential, yet pitfalls remain. Making informed decisions today ensures stronger foundations for tomorrow's projects.

Chinese threaded flanges play a vital role in construction and engineering projects. They offer secure connections in piping systems. These flanges are essential for maintaining pressure and preventing leaks. Their design allows for easy installation and dismantling. This flexibility is often crucial in maintenance and repairs.

When selecting threaded flanges, consider the material and size. Different projects need various specifications. Pay attention to the flange’s pressure rating. A mismatch can lead to serious issues. Quality control is key, so always check for flaws. If possible, consult with industry experts for guidance.

Tips: Always prioritize safety. Ensure proper alignment during installation. Double-check threads for any damages. A small oversight can lead to leaks. Take time to evaluate your choices carefully. The right flange can save time and money in the long run.

| Specification | Material | Pressure Rating | Size Range | Application Area |

|---|---|---|---|---|

| ASME B16.5 | Carbon Steel | 150 to 1500 | 1/2" to 24" | Oil and Gas |

| DIN 2633 | Stainless Steel | PN 10 to PN 40 | 15mm to 600mm | Chemical Processing |

| JIS B 2220 | Alloy Steel | 10K to 20K | 20A to 150A | Power Generation |

| ASME B16.47 | Duplex Stainless Steel | Class 150 to Class 2500 | 26" to 60" | Pipelines |

| BS 4504 | Forged Steel | 10 to 40 bar | DN 15 to DN 400 | Water Distribution |

When selecting threaded flanges for your projects, several key factors come into play. Material choice is essential. Stainless steel offers corrosion resistance, while carbon steel is durable and cost-effective. Understanding the environment in which the flanges will operate is crucial. Will they face high pressure or temperature? These conditions can dictate the type of flange that suits your needs.

Another important consideration is size and compatibility. Ensure the flanges fit your system requirements. An ill-fitting flange can lead to leaks or failures. It’s also vital to assess the threading style. Different applications may require specific types. A mismatch in threading can cause assembly issues.

Lastly, think about sourcing and availability. Some flanges may be hard to find while others are more common. A lack of options can stall progress on a project. Avoid rushing your decision. Take the time to evaluate different choices carefully. Compromises made in material or sizing can lead to problems later on.

When choosing threaded flanges from China, it’s essential to know the top manufacturers in 2026. These manufacturers are known for their quality and durability. They offer various sizes and specifications to suit different projects. Understanding their strengths can help you make informed decisions.

Tips: Always check the certifications of manufacturers. This can indicate their commitment to quality and safety. Don't hesitate to ask for samples. Testing a product before bulk orders can save you time and money.

Some manufacturers may not have the latest technology. It's crucial to assess the production process. Some may lack quality control measures, leading to inconsistency in products. Research reviews and feedback to identify reliable options.

A single poor choice can impact your entire project. So, remain cautious.

When selecting the right threaded flanges for your projects, material choice is crucial. Common options include carbon steel, stainless steel, and alloy materials. Each has its unique characteristics. Carbon steel is robust and economical. It's often used in general-purpose applications. However, it lacks corrosion resistance. This can be a drawback in harsh environments.

Stainless steel offers excellent resistance to corrosion. It is ideal for chemical processing or marine applications. But, it can be more expensive and may require special handling. Alloy materials, like duplex steel, combine strength with corrosion resistance. They are suitable for severe service conditions.

Tips: Consider the environment of your project. Will it face extreme temperatures or corrosive substances? Additionally, assess the required strength level. Sometimes, a less expensive option may suffice. Verify your project's specific needs before deciding. Reflect on long-term costs versus initial investment.

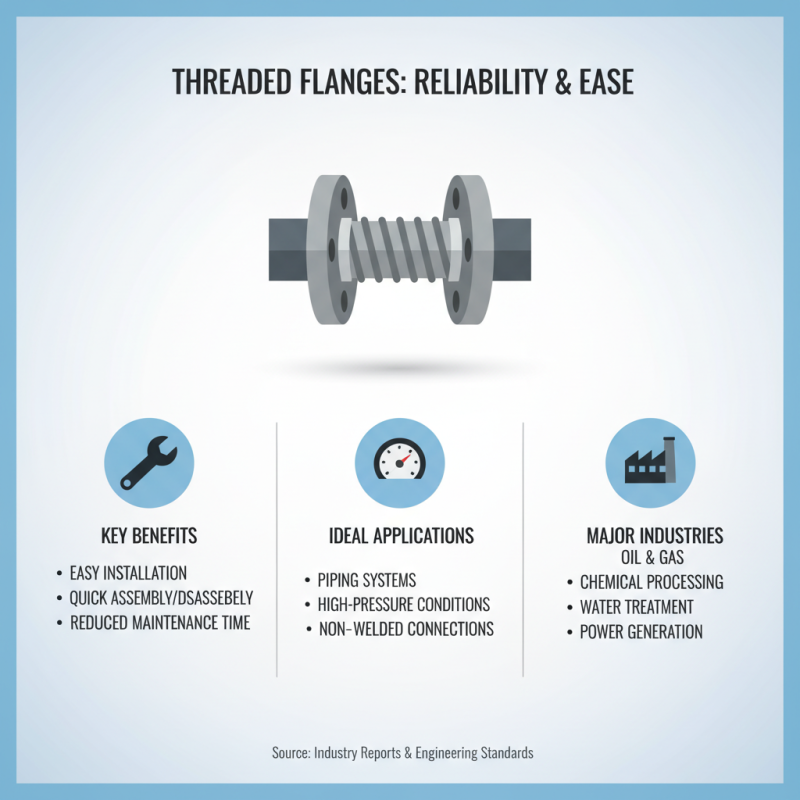

Threaded flanges are widely used across various industries for their reliability and ease of installation. These components excel in applications involving piping systems, where high-pressure conditions are prevalent. Their design allows for easy assembly and disassembly, making maintenance more manageable. Industries such as oil and gas, chemical processing, and water treatment often rely on threaded flanges.

In projects where space is limited, threaded flanges offer a compact solution. They can be installed in tight areas without requiring special tools. However, it is crucial to ensure proper torque settings during installation to prevent leaks. Misinstallation can lead to failures, especially under high-stress conditions. Engineers must pay attention to material compatibility as well; using the wrong material can compromise the integrity of the flange over time.

Additionally, while threaded flanges come with advantages, they may not be suitable for all applications. Factors like temperature fluctuations and corrosion should be considered during selection. Without thorough analysis, projects may face unexpected challenges. The balance between cost and reliability can lead to tough decisions. Careful evaluation is necessary to enhance project outcomes.