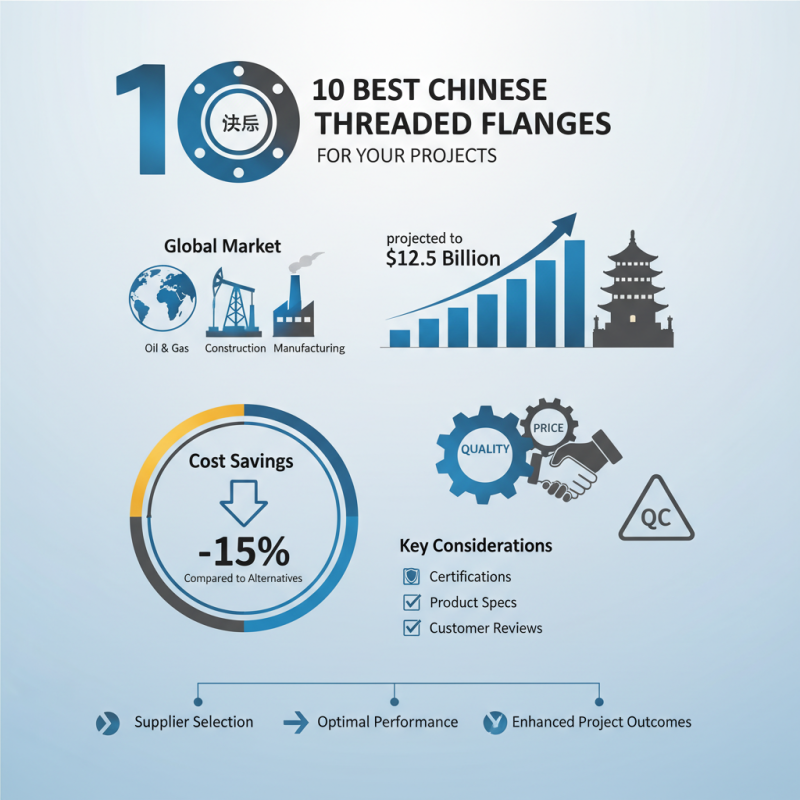

In recent years, the demand for high-quality Chinese threaded flanges has surged. The global flange market is projected to reach $12.5 billion by 2025, with Chinese manufacturers playing a crucial role. These flanges are vital components in various industries, including oil and gas, construction, and manufacturing. Their reliability and adaptability set them apart from others.

Moreover, Chinese threaded flanges often offer competitive pricing without compromising quality. Reports show that companies utilizing these flanges can cut costs by 15% compared to alternatives. Such economic benefits are hard to ignore, especially for projects on a budget. However, it's essential to evaluate the manufacturer's reputation and product specifications to ensure optimal performance.

While many suppliers provide extensive catalogs, not all Chinese threaded flanges meet international standards. Choosing the right supplier requires careful consideration. Pay attention to certifications and customer reviews. Quality control remains a significant concern. Ultimately, understanding the nuances of selecting flanges can save time and enhance project outcomes.

Threaded flanges are essential components in many piping systems. They provide an efficient way to connect pipes, valves, and fittings. Made from different materials, they suit various applications, including chemical processing and water supply.

In recent reports, the global demand for threaded flanges is projected to grow steadily. Research suggests a compound annual growth rate (CAGR) of about 4.1% from 2021 to 2026. This growth is visible across diverse industries. Engineers often prefer threaded flanges for their ease of installation and maintenance. Their design minimizes the risk of leaks, making them reliable choices.

However, not all threaded flanges perform equally. Some may not meet industry standards, leading to potential safety risks. Incomplete manufacturing processes can result in non-conforming flanges. Quality control is paramount. Regular inspections ensure that only safe and well-made products are used in projects. The industry must prioritize these factors to maintain safety and reliability.

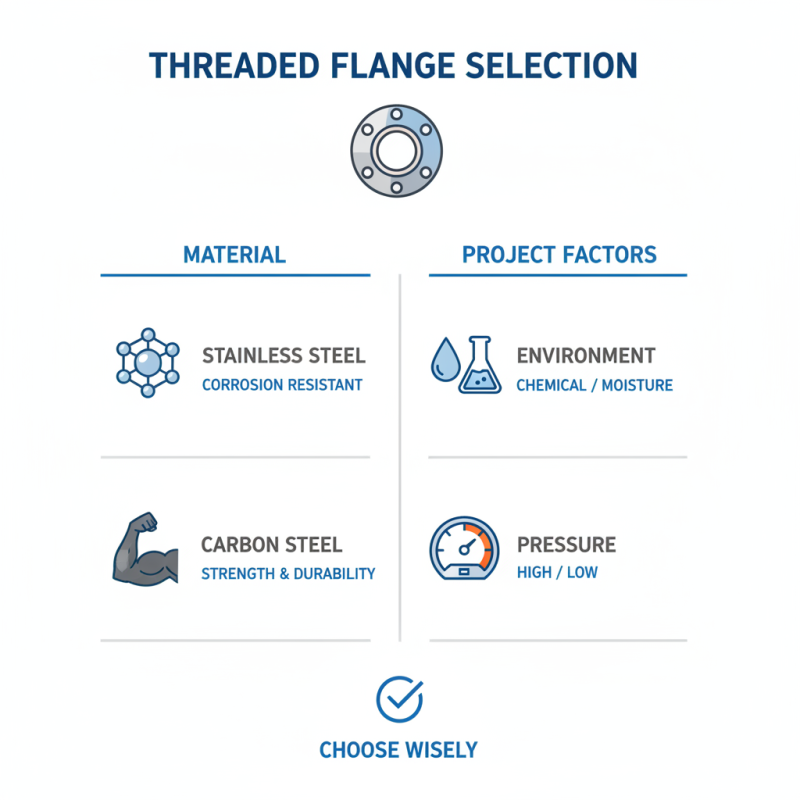

When selecting threaded flanges, several key factors demand attention. Material is paramount. Different projects require different materials. Stainless steel offers corrosion resistance, while carbon steel provides strength and durability. Choose based on the environment and pressure requirements.

Size also plays a critical role. The flange must fit the associated pipe perfectly. Measure carefully. An improper fit can lead to leaks or system failures. Pay attention to the diameter and pressure class to ensure compatibility.

Tips: Always verify the specifications against your project's needs. Understand the importance of threading quality. Poor threading can cause fitting issues down the line. Also, consider the flange's face type; this affects how well it seals.

Inadequate research might lead to costly mistakes. Projects can be derailed by wrong material choices or size mishaps. It’s worth consulting experts for significant investments. Take time to review all options before making a decision.

When selecting threaded flanges, the choice of manufacturer matters significantly.

Chinese manufacturers are well-known for their expertise in producing high-quality flanges. They offer a range of products suitable for various applications. Some produce flanges that boast excellent sealing properties. Others excel in durability, ensuring long-lasting performance. Each factory has unique strengths, contributing to a diverse market.

However, it’s essential to do thorough research. Not all manufacturers maintain the same quality standards. Some may promise more than they can deliver. Potential buyers should consider factors like certifications and customer feedback. An informed choice can prevent costly mistakes. It's also important to recognize that price may not always reflect quality. Sometimes, cheaper options might end up being unreliable, leading to future headaches.

Another point to reflect on is supply chain transparency. With many manufacturers, it can be challenging to trace the production process. Understanding where and how flanges are made can impact your project’s outcome. Building relationships with reliable suppliers can facilitate better communication. Ultimately, it’s a balance of price, quality, and trust in the manufacturing process. Always weigh your options carefully before making a decision.

When selecting threaded flanges, material quality plays a critical role. Chinese manufacturers often use various materials, such as carbon steel, stainless steel, and alloy steel. According to a recent industry report, about 60% of flanges on the market are made from carbon steel due to its cost-effectiveness. However, while carbon steel offers strength, it may lack corrosion resistance compared to stainless steel options.

Stainless steel threaded flanges are gaining popularity. They provide excellent durability and resistance to harsh environments, making them suitable for chemical processing. A study showed that these flanges can outperform carbon steel in lifespan by up to 40% in corrosive settings. Nevertheless, not all stainless steel grades are created equal. Minor variations in composition can lead to significant differences in quality and performance.

A concerning trend in the industry is the inconsistency in material sourcing. Some manufacturers do not adhere to rigorous quality standards. This can result in flanges that appear robust but fail under pressure. Buyers must carefully assess certifications and material guarantees before purchasing. Quality assurance is vital to avoid future complications in projects.

When installing threaded flanges, proper alignment is crucial. Misalignment can lead to leaks and failures. Ensure that the flange surfaces are clean before installation. Dust, dirt, or imperfections can hinder a tight seal. Use a suitable gasket to prevent leakage.

Routine maintenance is essential for longevity. Inspect the flanges regularly for signs of wear or corrosion. If you notice any damage, replace the flange immediately. Use the proper torque specifications when tightening bolts. Over-tightening can cause stress fractures. Always apply the correct lubricant.

Flanged joints often face pressure fluctuations. Understand the operating conditions to choose the right materials. Each project is unique, and the environment plays a big role. Remember, if you rush the installation or overlook maintenance, it can haunt you later. Stay attentive to detail for a reliable system.