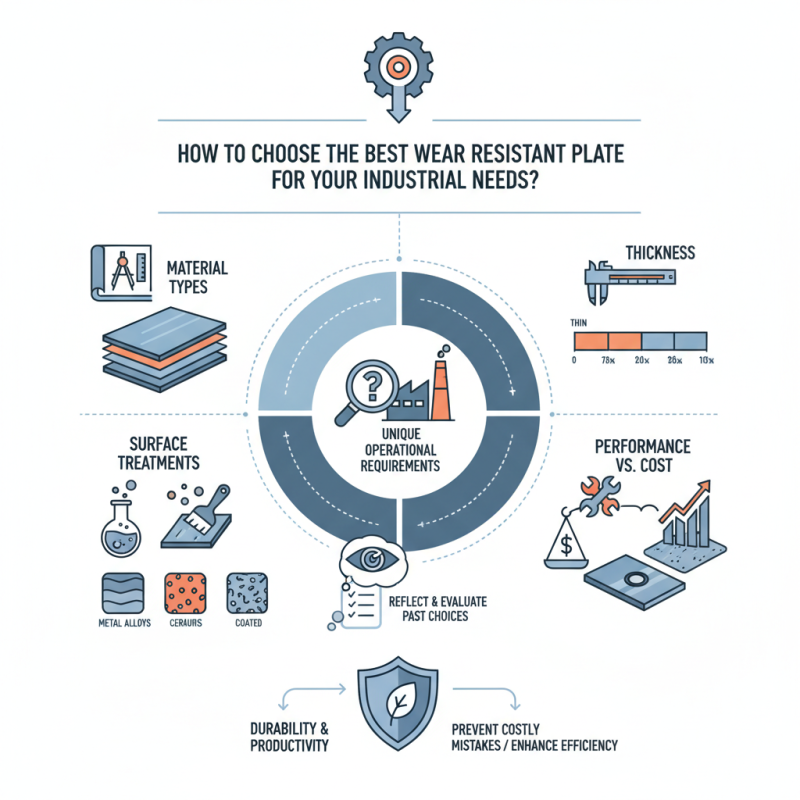

In the industrial sector, choosing the right "Wear Resistant Plate" can be a complex task. Experts highlight the importance of considering various factors. John Carter, a recognized specialist in material science, once stated, “Selecting the right wear plate is crucial for durability and productivity.” This emphasis on choice resonates throughout the industry.

Many businesses struggle with decisions about material types, thickness, and surface treatments. Some plates promise high durability but may fall short in real-world applications. The right selection often reflects a balance between performance and cost. Companies may invest in heavy-duty options but later find them unsuitable for specific tasks.

Understanding the unique requirements of your operations is essential. There is no one-size-fits-all solution. It's vital to reflect on past choices and evaluate their effectiveness. Attention to detail can prevent costly mistakes and enhance operational efficiency.

Wear resistant plates play a crucial role in various industries. They protect equipment from abrasion and impact. This leads to lower maintenance costs and longer equipment life. Industries such as mining, construction, and manufacturing rely heavily on these plates. An environment filled with heavy machinery can wear down components quickly. Choosing the right wear resistant plate becomes essential.

Understanding the specific needs of your operation is vital. Different applications require different materials. For example, high-impact applications may need tougher plates, while less vigorous environments can use lighter materials. The thickness of the plate can also affect performance. A thicker plate may offer better resistance, but it can also increase weight. This trade-off demands careful consideration.

It's easy to overlook some details. Many choose based solely on cost, but that can be misleading. A cheaper plate might save money initially but can lead to frequent replacements. These cycles could end up being more expensive in the long run. Evaluating the total cost of ownership is important. Real-world conditions can vary, and assumptions might not hold true. Always reassess your options carefully before making a decision.

When selecting wear-resistant plates, consider the material composition. Different alloy combinations affect durability and performance. Look for plates made from high-carbon steel or manganese steel. These options can withstand significant wear in harsh environments.

Next, the thickness of the plate is crucial. Thicker plates generally offer higher resistance to abrasion and impact. However, they can be heavier and more challenging to work with. Evaluate your application’s requirements carefully. Sometimes, a thinner plate may be sufficient and more cost-effective.

Lastly, the plate’s surface treatment should not be overlooked. Processes such as hardfacing or hardening can enhance resistance further. Yet, these treatments can vary in effectiveness. Always inquire about the specific properties of the surfaces. Remember, making an informed choice will save you time and money in the long run.

When selecting the right wear resistant plate, material choice is crucial. Different materials offer varying levels of durability and performance. For instance, steel plates are commonly used due to their strength. However, the hardness of the steel can differ. Some grades resist wear better than others, impacting overall efficiency.

On the other hand, ceramic materials are gaining attention. They often outmatch steel in abrasion resistance. Yet, they may be brittle, leading to potential fractures under sudden impact. This is a key trade-off to consider. Composite materials combine various elements to enhance performance. They can provide good wear resistance while maintaining flexibility.

Choosing a wear resistant plate isn't simple. Evaluating factors like weight, environment, and type of wear is vital. Understanding the specific needs of your application often requires thoughtful analysis. Ignoring these aspects can lead to costly mistakes. The right choice enhances productivity but requires careful consideration of material behavior in real-world conditions.

When evaluating wear-resistant plates, performance metrics are key. Hardness is often the first metric to consider. Plates made from high-carbon steel can achieve hardness levels exceeding 500 Brinell. This hardness typically implies better wear resistance. However, hardness alone doesn't guarantee durability in all conditions.

Tensile strength is another critical metric. Plates with high tensile strength resist breakage during heavy loads. For instance, a plate with 1200 MPa tensile strength can withstand significant stress without cracking. This is essential for industries like mining or construction, where material failure can lead to costly downtime.

Other factors include impact resistance and abrasion resistance. These metrics define a plate's ability to handle sudden stressors. Some reports suggest that properly tested wear plates can last up to 50% longer under abrasive conditions. However, relying solely on tested data can be misleading. Real-world applications often reveal that even the best-performing plates may fail in unexpected ways. Regular assessments are vital to adapt to changing conditions.

When considering wear-resistant plates, cost analysis is crucial. The initial purchase price often appears straightforward. However, lifetime costs reveal a different story. A recent industry report stated that maintenance can account for over 30% of total ownership costs. Thus, selecting a high-quality plate can save significant funds in the long run.

Budgeting should also factor in installation and potential downtime. Every day machinery is idle can cost businesses thousands in lost production. Some studies show that downtime linked to equipment failures can range between $5,000 to $20,000 per hour. Therefore, investing in durable plates pays off.

Moreover, varying material costs complicate these decisions. While some plates may offer lower upfront prices, they can wear down quickly, requiring replacements sooner. According to another industry source, premium wear-resistant steel can last up to 50% longer than cheaper alternatives. Ultimately, weighing these factors is essential for making informed financial decisions.