In today's industrial landscape, the importance of selecting the right Abrasion Resistant Plate cannot be overstated. According to a recent report by the Material Research Institute, the demand for abrasion resistant materials is expected to grow significantly, driven by the increasing need for durability and performance in various applications including mining, construction, and manufacturing. By 2025, the market for these materials is projected to reach over $2 billion, highlighting the critical role they play in enhancing equipment longevity and reducing maintenance costs.

Experts in the field emphasize the intricacies involved in choosing the perfect Abrasion Resistant Plate for specific needs. Dr. Emily Thompson, a materials science engineer, states, “Selecting an abrasion resistant plate requires a comprehensive understanding of the operational environment and the characteristics of the materials being handled.” This insight reveals that a personalized approach to material selection can lead to substantial improvements in operational efficiency and cost-effectiveness.

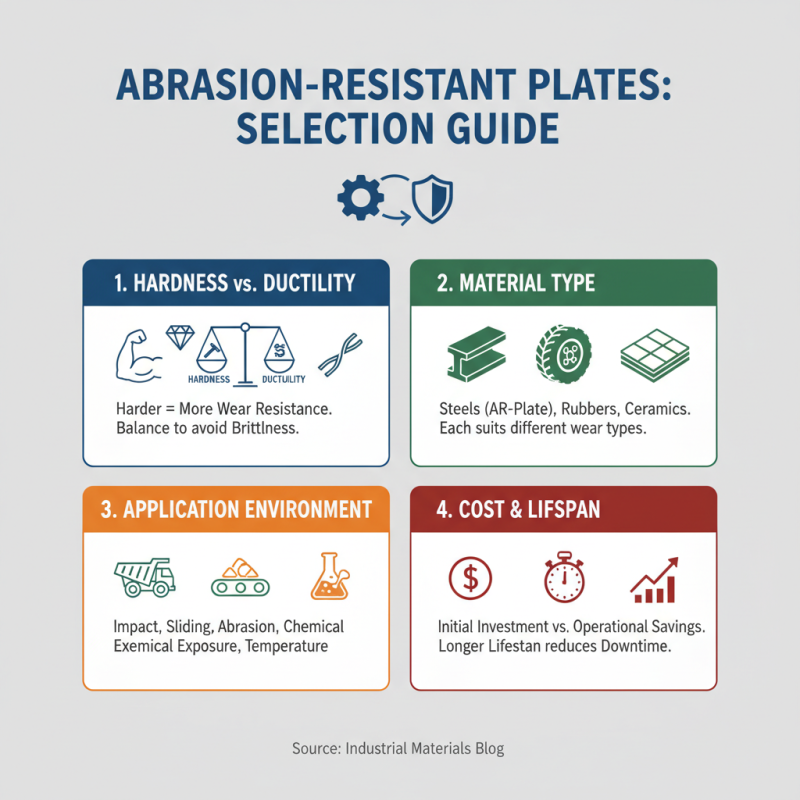

As industries continue to evolve and face challenges, the ability to choose the right Abrasion Resistant Plate is paramount. Factors such as hardness, thickness, and overall composition must be meticulously evaluated to ensure optimal performance. Businesses that invest time and resources in this selection process are likely to see significant returns in productivity and reliability, solidifying their competitive edge in the marketplace.

Understanding abrasion resistance is crucial in selecting materials that will endure harsh operational conditions. Abrasion resistance refers to the ability of a material to withstand wear due to friction and impact, which is a common challenge faced in various industrial applications. High-quality abrasion-resistant plates are designed to extend the service life of equipment, minimize replacement costs, and reduce downtime. Therefore, understanding the factors that contribute to abrasion resistance, such as material composition, hardness, and surface treatment, can greatly influence the performance of your applications.

The importance of abrasion resistance cannot be overstated, especially in industries such as mining, construction, and manufacturing. Materials that exhibit superior abrasion resistance help maintain operational efficiency and safety by preventing failures that could lead to downtime or accidents. When choosing an abrasion-resistant plate, it is essential to consider not only the specific demands of your application but also the environmental conditions it will face, such as temperature fluctuations or exposure to chemicals. By carefully evaluating these aspects, you can ensure that you select the best quality plate that meets your needs and protects your investments.

When selecting abrasion resistant plates, it's essential to consider several key factors to ensure that the material suits your specific needs. First, the hardness of the plate is crucial. Harder materials typically offer greater resistance to wear and tearing, making them suitable for applications with high impact or friction. It's important to balance hardness with ductility, as overly hard materials can become brittle, leading to potential failure in demanding environments.

Another factor to weigh is the thickness of the plate. Thicker plates can provide enhanced durability and protection, particularly in heavy-duty applications. However, increased thickness can also contribute to added weight and difficulties in handling and installation. Assessing the specific conditions and required performance levels for your application will guide you in selecting the optimal thickness.

Additionally, the manufacturing process of the plate can influence its performance characteristics. Different methods, such as quenching and tempering or water jet cutting, can yield varying results in terms of strength and wear resistance. Understanding these processes will help you make a better-informed decision tailored to the conditions in which the plate will be used, ensuring maximum efficiency and longevity in your operations.

When selecting an abrasion-resistant plate, understanding the various materials used in its production is crucial. The primary materials often include high-carbon steel, ceramic composites, and even polymer-based options. High-carbon steel is favored for its durability and ability to withstand significant wear and tear, making it ideal for heavy-duty applications in industries like mining and construction. Its strength is complemented by various heat treatment processes, which further enhance its toughness and resistance to abrasion.

On the other hand, ceramic composites offer a unique alternative by providing lightweight yet exceptionally tough solutions. These materials can be engineered to exhibit superior hardness, making them suitable for environments where weight savings are crucial without compromising performance. Additionally, some newer polymer-based abrasion-resistant plates are gaining traction due to their corrosion resistance and ease of installation. These materials are particularly useful in environments where traditional metals may fail due to chemical exposure or moisture. Understanding these varying properties will significantly influence the decision-making process when choosing the right abrasion-resistant plate for specific needs.

| Material Type | Hardness (Brinell) | Thickness Range (mm) | Typical Applications |

|---|---|---|---|

| AR400 | 360-410 | 3-25 | Mining, Construction Equipment |

| AR500 | 470-540 | 6-20 | Heavy Duty Equipment, Shot Blasting |

| Armadillo | 450-500 | 10-40 | Agricultural Machinery, Aggregate Processing |

| WearMax | 500-600 | 4-12 | Mining, Quarrying, Recycling |

When selecting the best abrasion resistant plate, understanding various ratings and standards is crucial for making an informed decision. Abrasion resistance is typically quantified using standardized tests that measure the material's ability to withstand wear under specific conditions. For instance, the ASTM G65 test is commonly utilized, where the plate is subjected to a specific abrasive environment, simulating real-world usage. The results provide a clear indication of how well the material will perform in abrasive service, guiding users towards the most suitable options for their applications.

Another important aspect to consider is the Rockwell hardness rating, which reflects the plate's hardness and, by extension, its resistance to wear and indentation. Higher Rockwell hardness values typically correlate with better abrasion resistance, though it's essential to balance hardness with other factors, such as ductility and impact resistance. Additionally, international standards like the ISO 3878 and DIN standards provide benchmarks for comparing different materials, ensuring that users can evaluate their options based on consistent criteria. By thoroughly understanding these ratings and standards, users can select the abrasion resistant plate that best meets their specific needs and operational demands.

This chart compares the abrasion resistance of various abrasion resistant plate ratings. The values represent the measured resistance in millimeters, illustrating how thickness correlates with durability.

Abrasion resistant plates are crucial components in various industries where wear and tear from heavy impact and friction are prevalent. In the mining industry, for instance, these plates are employed in equipment such as chutes, hoppers, and draglines, where they help protect machinery from the abrasive nature of materials like coal, minerals, and ore. By using high-quality abrasion resistant plates, companies can significantly reduce maintenance costs and downtime, while also extending the lifespan of their equipment.

Similarly, in the construction sector, abrasion resistant plates are utilized in several applications including crane and dump truck bodies, concrete mixers, and truck beds. Their ability to withstand harsh conditions and resist damage ensures that construction projects proceed smoothly without costly interruptions. Additionally, the manufacturing industry relies on these plates for factory floors and assembly lines, where machinery operates under constant friction and heavy loads. By integrating abrasion resistant plates, manufacturers enhance workplace safety and efficiency while minimizing the risk of equipment failures and associated repairs.