When it comes to industrial applications, choosing the right materials is crucial for ensuring efficiency and longevity. One such material that has gained significant attention in various sectors is the Wear Resistant Plate. As industries face increasing demands for durability and performance, the selection of the appropriate wear resistant solutions can greatly impact operational costs and productivity. According to Mark Thompson, a leading expert in the wear materials industry, "The right Wear Resistant Plate can mean the difference between continuous operation and costly downtime."

Wear Resistant Plates are designed to withstand harsh conditions, offering superior protection against wear and tear caused by friction, impact, and abrasion. Understanding the unique needs of a specific application is essential for selecting the best option available. Factors such as the type of materials being processed, environmental conditions, and the expected wear rates should all be taken into account. By carefully considering these elements, businesses can make informed decisions that enhance equipment performance and extend service life.

As the market evolves and new technologies emerge, the importance of selecting the best Wear Resistant Plate cannot be overstated. With options ranging from various materials to different thicknesses and coatings, it is vital for industries to stay informed about the latest advancements. Ultimately, making the right choice can lead to substantial long-term savings and improved efficiency in operations.

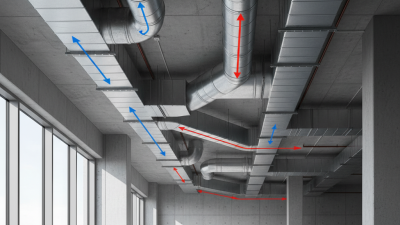

When selecting the best wear-resistant plates for your industrial applications, it is crucial to start by thoroughly understanding your specific needs. Different industries face unique challenges that can dictate the type of materials and specifications required for optimal performance. Factors such as the nature of the materials being handled, the working environment, and the type of machinery involved can significantly influence your choice.

For example, industries dealing with abrasive materials may require plates with higher hardness levels, while others might prioritize impact resistance.

Additionally, considering the environmental conditions in which the plates will be used is essential. Factors like temperature fluctuations, exposure to chemicals, and humidity levels can affect the plate's durability. It is also important to assess the expected wear rates and maintenance requirements associated with different types of wear-resistant plates.

By aligning your choice with the operational demands and environmental conditions specific to your application, you can ensure longer-lasting performance, reduced downtime, and overall cost efficiency in your industrial processes.

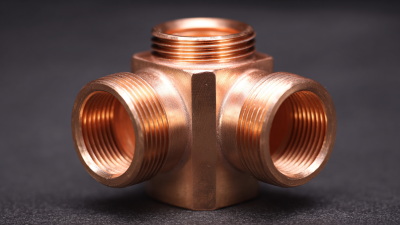

When selecting wear resistant plates for industrial applications, understanding the different materials available is crucial for making an informed decision. Common materials used in the manufacturing of wear resistant plates include carbon steel, alloy steel, and various types of ceramics. Carbon steel plates are widely recognized for their toughness and good weldability, making them suitable for a variety of applications where moderate wear and impact resistance are required. Alloy steel plates, often enriched with chromium and manganese, offer enhanced hardness and are designed to withstand severe wear conditions, making them ideal for heavy-duty industries such as mining and construction.

Another important category is ceramic-based plates, which are known for their superior hardness and abrasion resistance. These materials excel in environments where extreme wear is a concern, such as in materials handling and processing facilities. Additionally, composite materials, which combine different elements to maximize durability and performance, are increasingly used for specialized applications that demand lightweight yet robust solutions. Understanding the specific properties and applications of these materials will help businesses select the best wear resistant plates that align with their operational needs and budget constraints.

When selecting wear resistant plates for industrial applications, understanding the hardness and toughness ratings is crucial. Hardness measures a material's ability to withstand surface wear, while toughness determines its resistance to impact and fracture under stress. It's essential to strike a balance between these two properties to ensure optimal performance in demanding environments.

One important tip when evaluating wear resistant plates is to consider the specific conditions of your operation. If your application involves high impact forces, prioritize toughness alongside hardness. Conversely, in scenarios where abrasive materials are encountered frequently, focus more on the hardness rating, as this will help prolong the life of the plate.

Another tip is to review the testing standards used to determine these ratings. Different industries might employ various methods to assess performance, so understanding the criteria can provide insights into how well a particular plate will perform in your specific situation. Make sure to gather comprehensive data from trusted sources to make an informed decision.

When choosing wear-resistant plates for industrial applications, understanding the balance between cost-effectiveness and longevity is crucial. A 2022 report from the International Materials Performance Association highlights that companies can experience up to a 30% reduction in operational costs by investing in higher-quality wear-resistant materials. These plates are designed to withstand abrasive environments, thus extending the life of machinery and reducing downtime due to repairs or replacements. For example, a high-carbon alloy steel plate may have a higher initial cost but can last twice as long as traditional steel options in harsh conditions.

Tip: Conduct a thorough analysis of your operational conditions before making a decision. Identifying the type of wear your equipment will face can guide you in selecting the most suitable material. Factors such as impact loading, sliding wear, and abrasion resistance should all be considered.

Moreover, it's important to assess the total lifecycle costs of the wear-resistant plates. A study by the Wear Materials Research Institute found that while some plates might have lower upfront costs, the expenses related to maintenance, downtime, and replacement can significantly offset these savings over time. By taking a long-term view, companies can better gauge the true cost-effectiveness of their investment.

Tip: Collaborate with suppliers to obtain performance data and case studies from similar applications. This may provide valuable insights into the longevity and durability you can expect, allowing for a well-informed purchasing decision.

| Material Type | Cost per Square Meter ($) | Average Lifespan (Years) | Hardness (Brinell) | Typical Applications |

|---|---|---|---|---|

| AR400 | $45 | 4-6 | 400 | Mining, Construction |

| AR500 | $55 | 5-7 | 500 | Heavy Equipment, Military |

| Hardox 450 | $70 | 6-8 | 450 | Agriculture, Recycling |

| Cortenegro | $60 | 4-5 | 500 | Belt Conveyors, Chutes |

| WearMax | $80 | 7-10 | 550 | Mining, Construction Equipment |

When selecting a wear-resistant plate for industrial applications, assessing manufacturer certifications and industry standards for durability is crucial. Many industries face stringent requirements, and adhering to recognized standards ensures that the selected plate not only meets performance criteria but also contributes to operational efficiency. According to the American Society for Testing and Materials (ASTM), wear-resistant materials must fulfill specific hardness and impact resistance metrics, often outlined in ASTM A532 or ASTM A572 specifications. In sectors like mining and construction, utilizing materials that comply with these standards can significantly reduce maintenance costs and extend the lifespan of machinery.

Tips: Before finalizing your choice of a wear-resistant plate, verify whether the manufacturer has certifications like ISO 9001 or compliance with safety standards such as OSHA. This indicates a commitment to quality control and durability, ensuring that the plate can withstand harsh working environments. Furthermore, consider suppliers that provide test reports or third-party validations; these documents offer insights into the material’s performance under various conditions.

Incorporating industry standards can guide your decision-making process. For example, the Minerals Industry Safety and Health Centre suggests that selecting wear plates that meet a minimum hardness level of 500 Brinell can help mitigate wear in applications with high abrasion. Analyzing these certifications not only provides assurance of quality but positions your operation for long-term success in demanding environments.