In the fast-evolving landscape of industrial applications, selecting the right Seamless Boiler Tubes is critical for ensuring efficiency, safety, and longevity. According to a recent report by Market Research Future, the global seamless tube market is projected to reach USD 4.2 billion by 2027, with a substantial portion driven by the demand within the power generation and chemical processing sectors. These figures underscore the growing importance of choosing the appropriate materials and specifications to meet diverse operational requirements.

As stated by industry expert Dr. John Harris, a leading metallurgical engineer, “The performance of boiler systems heavily relies on the integrity and quality of the seamless tubes used; a poor choice can lead to catastrophic failures and elevated maintenance costs.” Therefore, understanding the various factors—such as material grade, manufacturing processes, and applicable standards—is essential for any industrial operation aiming to enhance performance while minimizing risks. With the right insights, businesses can make informed decisions that align with their specific needs and regulatory requirements, ensuring optimal operational efficiency and safety in their systems involving Seamless Boiler Tubes.

Seamless boiler tubes play a crucial role in various industrial applications, especially in the energy sector. These tubes are primarily used in high-pressure environments, such as boilers and heat exchangers, where they are exposed to elevated temperatures and pressures. One of the key advantages of seamless boiler tubes is their ability to withstand significant stress without the risk of failure, making them ideal for applications ranging from power generation to petrochemical processing. According to a report by the Global Market Insights, Inc., the seamless tube market is expected to grow at a compound annual growth rate (CAGR) of over 4% from 2021 to 2027 due to increased demand in these sectors.

The applications of seamless boiler tubes extend beyond traditional use in power plants. They are also crucial in industries such as oil and gas, where they are utilized in various components, including pipelines and refining units. The American Society of Mechanical Engineers (ASME) sets stringent standards for boiler tubes to ensure safety and reliability. For instance, seamless boiler tubes are manufactured under the specifications of ASTM A335, which requires rigorous testing and quality assurance processes to meet the needs of high-pressure applications. This emphasis on quality underscores the importance of choosing the right material, as the performance of these tubes directly impacts the efficiency and safety of industrial operations.

When selecting seamless boiler tubes for industrial applications, several key factors must be considered to ensure optimal performance and safety. First, the material composition of the tubes plays a critical role in their durability and resistance to extreme temperatures and pressures. Common materials include carbon steel, alloy steel, and stainless steel, each offering varying levels of corrosion resistance and strength. It is vital to analyze the specific requirements of your application, including the operational conditions and the fluids being transported, to choose the appropriate material.

Another important factor is the tube specifications, including dimensions and wall thickness. Seamless boiler tubes come in various sizes, and selecting the correct diameter and wall thickness is essential for achieving the required pressure ratings and mechanical properties. Additionally, compliance with industry standards and certifications is crucial to ensure the tubes meet safety and quality requirements. Assessing the manufacturing processes used in producing the tubes, such as extrusion or rotary piercing, can also provide insights into their reliability and structural integrity, ultimately impacting the overall efficiency and lifespan of the boiler system.

| Factor | Description | Importance | Common Standards |

|---|---|---|---|

| Material Composition | The type of alloy used in the tube construction affects strength and corrosion resistance. | High | ASTM A335, ASTM A106 |

| Diameter and Thickness | Outer diameter and wall thickness impact the pressure handling capacity. | Critical | ASME B36.10, ASME B36.19 |

| Temperature and Pressure Ratings | Evaluate the operational conditions to select tubes that meet required ratings. | Very High | ASME Codes, EN 10216 |

| Corrosion Resistance | Consider environmental factors that may cause corrosion to choose suitable materials. | High | NACE MR0175 |

| End Connections | Compatibility with existing systems based on connection types and specifications. | Moderate | API 5L |

| Manufacturing Process | The method of production can affect quality and performance attributes. | Important | ASTM A53 |

When selecting seamless boiler tubes for industrial applications, material choice is paramount to ensuring optimal performance and longevity. The most commonly used materials include carbon steel, alloy steel, and stainless steel, each offering distinct advantages depending on the operational environment. According to the American Society of Mechanical Engineers (ASME), carbon steel is widely utilized for applications involving moderate temperatures and pressures, while alloy steels exhibit superior strength and resistance to oxidation, making them suitable for high-temperature environments.

The selection criteria often hinge on mechanical properties and corrosion resistance. Research published in the Journal of Materials Science indicates that the addition of chromium and molybdenum in alloy steel significantly enhances its performance in high-stress scenarios, reducing the risk of catastrophic failures. Additionally, seamless boiler tubes made from stainless steel, particularly those with high nickel content, provide excellent resistance to corrosive substances, which is critical in industries such as petrochemicals where fluid corrosiveness can vary drastically. It is essential for engineers to consider these material properties in conjunction with the specific thermal and mechanical loads anticipated in their applications to guarantee safety and efficiency.

When assessing the size and dimensions of seamless boiler tubes for industrial applications, it is crucial to understand the specific requirements dictated by your project. The outer diameter (OD) and wall thickness are two fundamental dimensions that determine a tube’s capacity to withstand pressure and temperature, which are critical for boiler operations. Typically, industry standards dictate specific sizes, such as nominal pipe sizes (NPS) and schedules, which help in defining the wall thickness. A careful evaluation of these dimensions will ensure that the tubes are suitable for the intended operational pressures and thermal conditions.

In addition to OD and wall thickness, the length of seamless boiler tubes often plays a significant role in installation and performance. Standard lengths can vary, but custom lengths may be required depending on the configuration of your system. It's essential to consider how these dimensions integrate with the existing infrastructure, including connections and fittings. Moreover, the positioning of the tubes within the boiler design can influence heat transfer efficiency and overall performance, making it imperative to align the size and dimensions of the tubes with the operational design of the boiler system. Such considerations will ultimately facilitate better energy efficiency and longevity of the equipment.

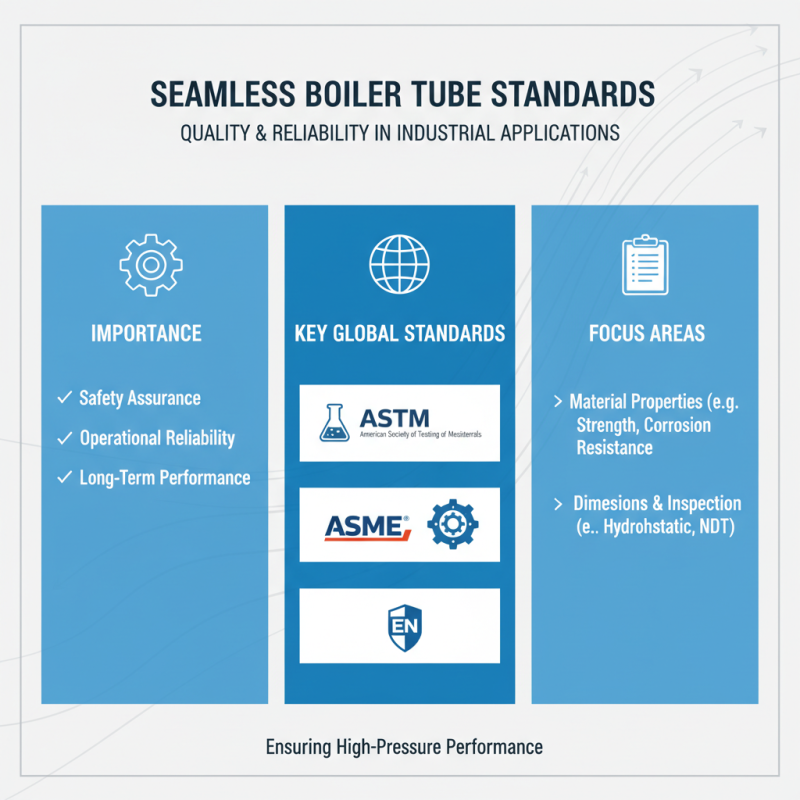

When selecting seamless boiler tubes for industrial applications, understanding the relevant quality standards and certifications is crucial to ensuring safety, reliability, and performance. Various international standards govern the manufacturing and testing of these tubes, including ASTM, ASME, and EN standards. These guidelines establish the requirements for material properties, dimensions, and testing methodologies, significantly affecting the overall quality and longevity of the tubes used in high-pressure environments.

Certifications play a vital role in confirming that manufacturers adhere to these quality standards. Industry-recognized certifications such as ISO 9001 (Quality Management Systems) or ISO 14001 (Environmental Management) are indicators of a manufacturer's commitment to quality and sustainability. Additionally, compliance with specific material standards, such as ASTM A335 for ferritic alloy steels, assures users of the tubes' suitability for demanding applications, including power generation and petrochemical processes. Choosing products that meet these established certifications can provide confidence in their performance, reducing the risk of failures and costly downtime in industrial operations.