Choosing the right flange manufacturer is a critical step in any project involving piping and joint connections, particularly in industries such as oil and gas, petrochemical, and waterworks. According to a report by the Global Flanges Market Research Institute, the global flange market is projected to reach $30 billion by 2025, driven by the increasing demand for high-quality piping systems that can withstand extreme conditions. As industries demand enhanced safety and reliability, selecting a reputable flange manufacturer becomes paramount.

The intricacy of flange manufacturing involves various materials, standards, and specifications that can significantly impact the performance and durability of the final product. In fact, a study by the American Society of Mechanical Engineers (ASME) indicates that improper flange selection can lead to up to 30% of all pipeline failures. With the market currently saturated with numerous manufacturers, it is essential for project managers and engineers to thoroughly evaluate their options. Key factors such as manufacturing capabilities, compliance with international standards, and proven track records are crucial in identifying a flange manufacturer that meets the specific needs of any project. By making informed choices, stakeholders can ensure the integrity and longevity of their systems while optimizing overall project success.

When choosing the right flange manufacturer for your project, it is essential to first understand your specific project requirements. Start by identifying the type of flange you need, whether it is a weld neck, slip-on, or blind flange. Each type serves different purposes and has unique specifications that cater to various applications. Consider the material composition—carbon steel, stainless steel, or exotic alloys—based on the environmental conditions and the fluid types your project will encounter.

Additionally, think about the dimensions and pressure ratings required for your project. Accurate measurements and adherence to industry standards will ensure compatibility with existing systems. It’s also vital to assess the manufacturer's capability in delivering custom designs if standard options do not meet your needs. Furthermore, inquire about the manufacturer’s quality control processes and certifications, as these factors contribute significantly to the reliability and safety of the flanges you will be using. By thoroughly evaluating these aspects, you will be able to select a flange manufacturer that aligns perfectly with your project’s requirements.

When selecting a flange manufacturer for your project, evaluating their credentials and experience is crucial. According to a report by the Global Flanges Market, the demand for high-quality flanges has increased by approximately 8% annually over the past few years, driven by growth in industries such as oil and gas, construction, and water treatment. This surge underscores the need for manufacturers who not only meet high production standards but also have a proven track record in the industry.

A reputable flange manufacturer should possess relevant certifications, such as ISO 9001:2015, which ensures a quality management system that can effectively meet customer needs. Furthermore, reviewing their experience in specific applications, like high-pressure or specialized material flanges, can provide insights into their capabilities. The 2023 Industry Analysis Report highlights that companies with over 10 years of experience tend to maintain better quality controls and demonstrate more innovative solutions, ultimately leading to improved project outcomes. By focusing on these factors, project managers can make more informed decisions that align with their operational goals.

| Manufacturer Location | Years of Experience | Certifications | Production Capacity (Units/Month) | Specializations |

|---|---|---|---|---|

| North America | 15 | ISO 9001, ASME | 5000 | Standard & Custom Flanges |

| Europe | 20 | CE Marked, ISO 14001 | 3000 | High-Pressure Flanges |

| Asia | 10 | ISO 9001, API | 8000 | Weld Neck, Slip-On Flanges |

| South America | 12 | ISO 9001, OHSAS 18001 | 2000 | Custom Fabricated Flanges |

| Middle East | 8 | ISO 9001, ASME | 4000 | Marine Flanges |

When choosing a flange manufacturer, understanding the material options available is crucial. Flanges can be produced from various materials, including carbon steel, stainless steel, and alloy materials, each with distinct properties suited for different applications. According to a report by Grand View Research, the global flanges market was valued at approximately $15 billion in 2022, with a significant demand for stainless steel flanges in industries like oil and gas, which comprise over 30% of the market usage. This highlights the importance of material choice in ensuring durability and performance.

Moreover, adhering to industry standards is essential when selecting flange materials. Organizations such as ASTM (American Society for Testing and Materials) and ASME (American Society of Mechanical Engineers) provide specifications that manufacturers must meet for safety and reliability. For instance, ASME B16.5 outlines the dimensions and tolerances of flanges used in piping systems, ensuring compatibility and performance under pressure. A comprehensive study by ResearchAndMarkets indicates that compliance with such standards can significantly reduce maintenance costs by up to 25%, reinforcing the importance of selecting a manufacturer well-versed in these industry norms.

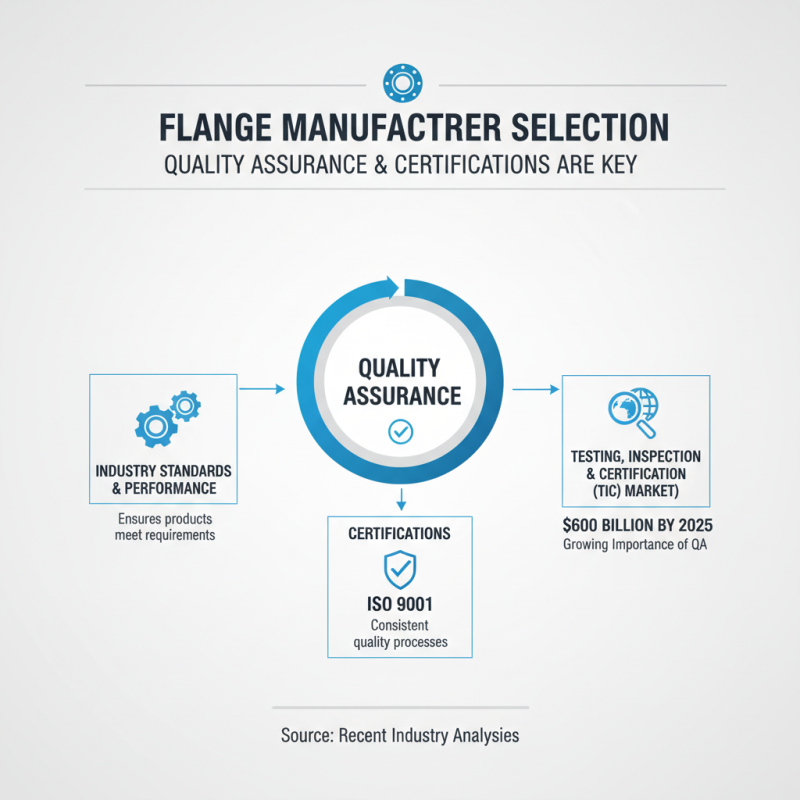

When selecting the right flange manufacturer for your project, assessing their quality assurance practices and certifications is crucial. Quality assurance ensures that the products meet industry standards and performance requirements. Manufacturers often exhibit certifications such as ISO 9001, which signal their commitment to maintaining consistent quality in their processes. According to recent industry analyses, the testing, inspection, and certification (TIC) market is projected to reach significant growth, estimated at $600 billion by 2035. This underscores the increasing importance of quality assurance across various sectors.

Tips: When evaluating manufacturers, inquire about their quality management systems and whether they have undergone third-party audits. This will help ensure their practices align with international standards. Furthermore, consider the types of testing they perform; for instance, does the manufacturer utilize non-destructive testing (NDT) methods? Such testing techniques are essential for industries like aerospace, where material integrity is paramount.

Moreover, a manufacturer’s adherence to environmental and sustainability certifications can be indicative of their overall quality ethos. The rise of initiatives around product carbon footprint certification demonstrates the market's shift towards sustainable practices. Choosing a manufacturer that values both quality and sustainability can play a critical role in the success of your project in an increasingly eco-conscious industry.

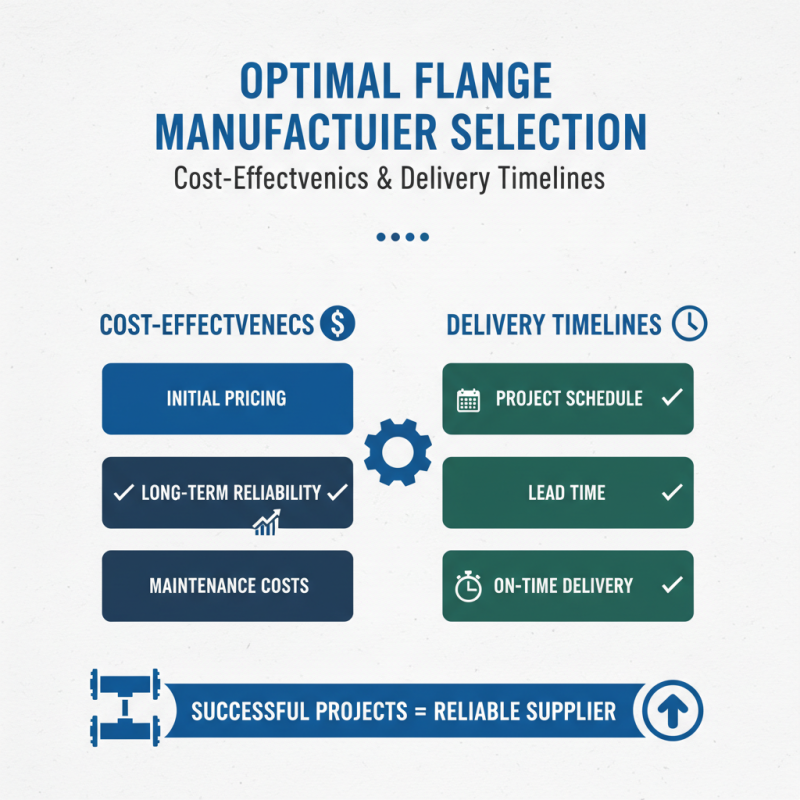

When selecting a flange manufacturer, analyzing cost-effectiveness and delivery timelines is critical to ensure your project's success. Flanges serve as vital components in piping systems, and choosing the right supplier can significantly impact both your budget and project schedule. Cost-effectiveness involves not just the initial pricing of the flanges but also the long-term reliability and maintenance costs. A slightly higher upfront price for a proven manufacturer could save you from costly repairs or replacements down the line.

To navigate this landscape effectively, consider these tips: First, request detailed quotations from multiple suppliers, ensuring you assess long-term value rather than just initial costs. Second, inquire about the manufacturer's quality certifications and warranty options to gauge their commitment to reliability. Lastly, ask for clear delivery timelines. A supplier that consistently meets deadlines can help keep your project on track and avoid costly delays.

By prioritizing both cost and delivery when evaluating flange suppliers, you can make informed decisions that align with your project needs. Keep an eye on how these factors interplay, as a well-timed delivery of high-quality flanges can make all the difference in the success of your engineering operations.