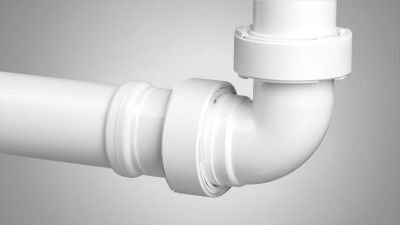

When it comes to plumbing projects, selecting the right components can significantly affect the overall functionality and reliability of the system. One essential fitting that often plays a crucial role in the installation is the PVC elbow with thread. This versatile plumbing component is designed to create smooth, angled turns in piping while allowing for easy connections to threaded fittings. Understanding the importance of choosing the appropriate PVC elbow with thread is crucial for ensuring efficient water flow and minimizing the risk of leaks in any plumbing setup.

In this guide, we will explore the various factors you should consider when selecting the right PVC elbow with thread for your specific plumbing needs. From understanding the various sizes and angles available to recognizing the importance of quality and material compatibility, making an informed choice can save you time, effort, and money in the long run. Additionally, we will provide insights into common applications and best practices for installation to help you achieve a professional result, whether you're a DIY enthusiast or a seasoned plumber. With the right guidance, you will be better equipped to navigate the options and make the best selection for your plumbing project.

When it comes to plumbing, PVC elbows play a crucial role in guiding pipes around corners and changes in direction. These fittings are designed to connect two pieces of pipe at an angle, most commonly 90 or 45 degrees, making them essential for effective drainage and distribution systems. According to a report from the Plastics Industry Association, the demand for PVC pipes and fittings has seen a consistent rise, reflecting an increasing reliance on durable and lightweight materials in plumbing applications.

There are several types of PVC elbows available, each suited to specific plumbing requirements. The two primary options are threaded and slip PVC elbows. Threaded elbows have male or female threads that allow for easy connection to other threaded components, while slip elbows require the pipes to be glued into place, offering a permanent solution. Understanding the differences in these fittings can help professionals and DIY enthusiasts alike make informed choices to ensure optimal flow and reliability in their plumbing systems. Industry standards indicate that properly selected fittings can reduce the risk of leaks and system failures, underscoring the importance of choosing the right type based on the project’s specific needs.

When it comes to selecting the right PVC elbow with thread for plumbing applications, understanding the significance of threads in PVC fittings is paramount. Threads provide a vital connection that ensures a leak-proof assembly. According to the American Society of Plumbing Engineers (ASPE), improperly threaded fittings can lead to significant water loss and increased maintenance costs. A report from the Plastic Pipe and Fittings Association (PPFA) indicates that failures due to poor threading account for approximately 15% of plumbing installation issues, emphasizing the need for high-quality threaded joints.

Threads play a crucial role in achieving a secure fit between different sections of plumbing systems. The precise engineering of threads allows for easy assembly and disassembly, making repairs or modifications convenient. Studies from the International Association of Plumbing and Mechanical Officials (IAPMO) highlight that the use of well-manufactured threaded PVC fittings can significantly enhance the longevity and reliability of plumbing systems. Moreover, twisted or stripped threads can undermine the structural integrity of joints, making it essential to choose the right threading standard, such as NPT (National Pipe Thread) or BSP (British Standard Pipe), based on regional plumbing codes and practices.

Furthermore, comprehensive research indicates that the effectiveness of PVC threaded fittings is also influenced by the chemical compatibility of the materials involved. PVC, known for its corrosion resistance, paired with properly threaded fittings can withstand various environmental stresses. The Plumbing-Heating-Cooling Contractors Association (PHCC) notes that proper adherence to threading specifications not only improves connection reliability but also minimizes the risk of leaks, which can lead to costly damage and repairs. Ensuring that the right threading type is utilized is, therefore, a crucial step in safeguarding plumbing systems against premature failure.

When selecting the right PVC elbow with thread for your plumbing needs, it is essential to consider several key factors to ensure durability and compatibility. First, assess the diameter and size of the elbow to guarantee it fits seamlessly in your existing plumbing system. Typically, elbows come in various sizes, and understanding your specific needs will help avoid leaks and ensure proper flow. Second, consider the angle of the elbow, whether it's a 90-degree or 45-degree turn. This choice can significantly affect the efficiency of your plumbing layout and the flow of liquids through your system.

Another crucial aspect to examine is the thread type on the PVC elbow, which needs to match the other fittings in your plumbing system. Different thread types, such as tapered or straight threads, have distinct sealing characteristics that can impact functionality. Additionally, ensure that the material is resistant to the specific substances it will transport, as certain chemicals can degrade PVC over time. By carefully considering these factors, you will be better equipped to choose a PVC elbow that meets your plumbing requirements effectively.

| Dimension (inches) | Thread Type | Pressure Rating (psi) | Temperature Resistance (°F) | Applications |

|---|---|---|---|---|

| 1/2 | Female | Schedule 40 - 150 | 140 | Residential plumbing |

| 3/4 | Male | Schedule 40 - 150 | 140 | Irrigation systems |

| 1 | Female | Schedule 40 - 150 | 140 | Drainage systems |

| 1 1/4 | Male | Schedule 40 - 150 | 140 | Industrial applications |

| 1 1/2 | Female | Schedule 40 - 150 | 140 | Commercial plumbing |

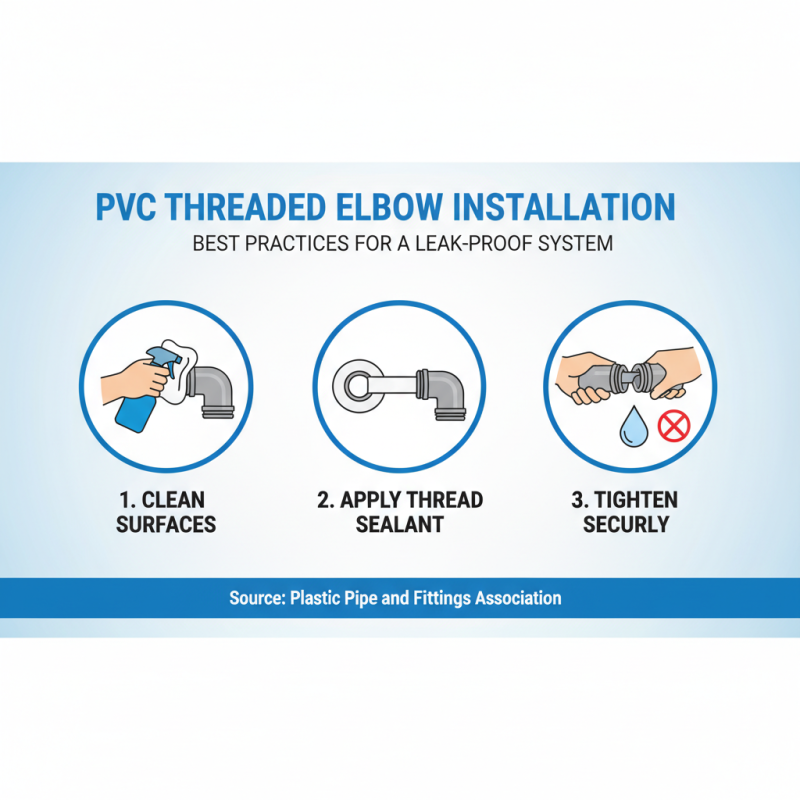

When installing PVC elbows with threads, adhering to best practices is essential for ensuring a leak-proof and durable plumbing system. One of the most common mistakes is neglecting to properly clean the surfaces before making connections. According to the Plastic Pipe and Fittings Association, clean joints are critical for achieving optimal adhesion and preventing failures. Always use a suitable cleaner to eliminate any dust or grease, ensuring a smooth bonding surface.

Another tip is to avoid over-tightening the threaded connections. While it might seem logical to tighten as much as possible, over-tightening can lead to stress fractures in the PVC material. The American Society of Mechanical Engineers suggests following the manufacturer's torque specifications to avoid compromising the integrity of the joint. Ensuring that your threads are adequately lubricated with a sealant can prevent leaks without the need for excessive force.

Finally, consider temperature and pressure ratings when selecting your PVC elbows. Industry research indicates that PVC fittings have distinct performance ratings, and using components rated for higher temperatures or pressures not suitable for your application can lead to premature failure. Always review product specifications and application guidelines to choose the right PVC elbow that fits your plumbing situation.

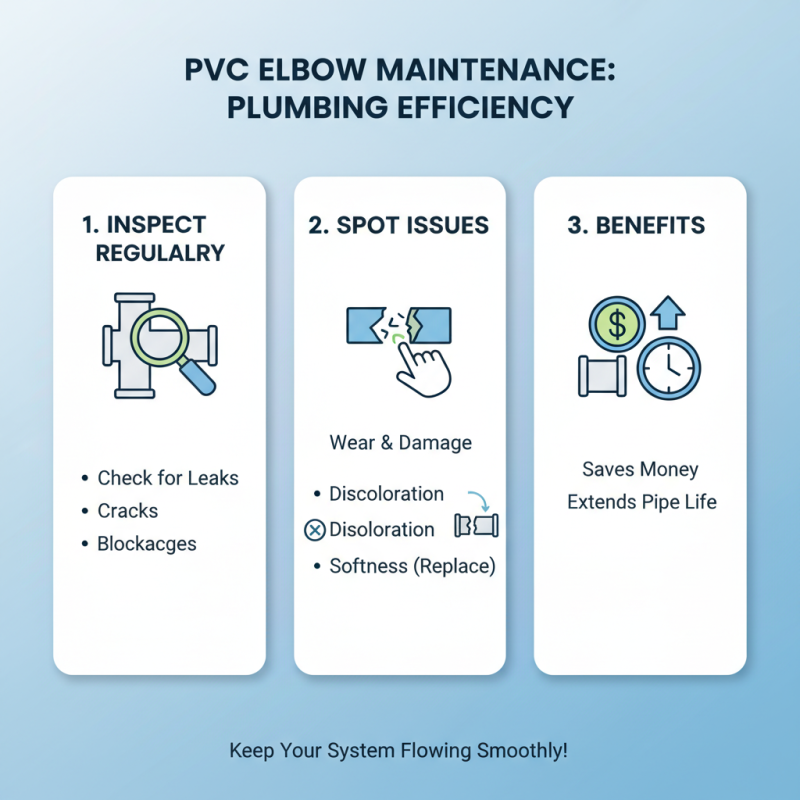

Maintaining your PVC elbows is crucial for ensuring the efficient operation of your plumbing system. Regular inspections can help you spot potential issues such as leaks, cracks, or blockages. When performing maintenance, check for signs of wear or damage that could impede water flow or lead to further complications. If you notice discoloration or softness in the elbow, it may be time for replacement. Keeping your plumbing system well-maintained not only saves you money on repairs but also extends the life of your piping infrastructure.

Troubleshooting PVC elbows involves identifying and resolving common issues that can arise over time. For instance, if you experience water flow problems, start by examining the elbow fittings for proper installation and any signs of buildup inside that may restrict flow. Also, ensure that the threaded connections between elbows and pipes are secure and free of leaks. If there are persistent issues, you may need to disassemble the joint for a more thorough inspection. By addressing these concerns promptly, you can prevent more significant plumbing issues from developing, ensuring a seamless and efficient plumbing experience.