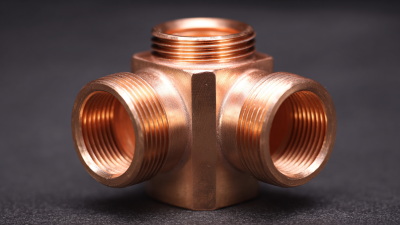

In the realm of plumbing systems, the significance of various fittings cannot be overstated. Among these, the Copper Elbow Fitting stands out as an essential component, known for its versatility and reliability. This fitting, shaped like an elbow, allows plumbers to change the direction of piping, enabling the seamless integration of plumbing networks. Its durable material not only ensures longevity but also offers excellent resistance to corrosion, making it a preferred choice for both residential and commercial applications.

Understanding the use and installation of a Copper Elbow Fitting is crucial for plumbing professionals and DIY enthusiasts alike. This fitting is typically employed to create angled connections between pipes, allowing for efficient routing in complex plumbing layouts. Whether it’s directing water flow under sinks, around corners, or in intricate boiler setups, the Copper Elbow Fitting proves to be indispensable. As we delve deeper into its applications, benefits, and installation techniques, it becomes evident that mastering the use of this fitting is key to achieving a dependable and effective plumbing system.

Copper elbow fittings are essential components in plumbing systems, designed to allow pipes to change direction with ease. Typically made from high-quality copper, these fittings are favored for their durability and resistance to corrosion. According to industry reports, copper pipe joins provide superior heat transfer and are often used in various plumbing applications, including domestic water distribution and heating systems. This flexibility in design is crucial for navigating the complex layouts of modern plumbing.

These fittings come in various angles, with 90-degree and 45-degree elbows being the most common. Their effectiveness in maintaining fluid flow while redirecting it makes them invaluable in creating efficient plumbing systems. Data from the American Copper Council indicates that copper's thermal conductivity and malleability make it a preferred choice for plumbing applications, which can lead to energy savings and a longer lifespan for the entire system.

Tips: When working with copper elbow fittings, ensure that you properly clean and prepare the pipe ends to ensure a tight seal. Additionally, always check local plumbing codes to ensure compliance with regulations. Opt for a reputable source for your fittings to guarantee the quality and performance of your plumbing installation.

Copper elbow fittings are essential components in plumbing systems, functioning to connect two pipes at an angle, facilitating directional changes in water flow. There are several types of copper elbow fittings, each serving unique purposes based on the requirements of a plumbing project. The most commonly used types include the 45-degree elbow and the 90-degree elbow. The 90-degree elbow allows for sharp turns in piping, making it ideal for tight spaces, while the 45-degree elbow is often utilized in applications that require a gentler angle to reduce turbulence in fluid flow.

When choosing copper elbow fittings, it's important to consider factors such as pipe diameter and the pressure rating of your plumbing system. According to the American Society of Plumbing Engineers (ASPE), using the correct type of fitting can greatly influence the efficiency and longevity of a plumbing installation. For example, utilizing fittings with a higher pressure rating can help minimize leaks and damage, extending the life of the plumbing system.

Tips: Always ensure that the fittings are properly soldered or crimped to maintain a leak-free connection. It's advisable to clean the pipe ends thoroughly before installation to remove any debris or oxidation. Also, consider using fittings that meet the relevant industry standards, such as those set by the ASTM, to ensure quality and reliability in your plumbing systems.

| Type of Copper Elbow Fitting | Angle | Common Uses | Material Thickness |

|---|---|---|---|

| 90 Degree Elbow | 90° | Change direction of pipe | 0.040 inches |

| 45 Degree Elbow | 45° | Smooth transitions | 0.040 inches |

| Reducing Elbow | Various | Connecting different pipe sizes | 0.045 inches |

| Short Radius Elbow | 90° | Compact spaces | 0.050 inches |

| Long Radius Elbow | 90° | Standard use in plumbing | 0.045 inches |

Copper elbow fittings are essential components in plumbing systems, primarily used to connect two pipes at an angle, allowing for changes in direction within the piping layout. These fittings are particularly valued for their durability, corrosion resistance, and ability to withstand high temperatures, making them an ideal choice for various plumbing applications. In residential and commercial settings, copper elbow fittings are commonly utilized to redirect water flow between pipes, ensuring an efficient plumbing system that maintains optimal pressure and flow.

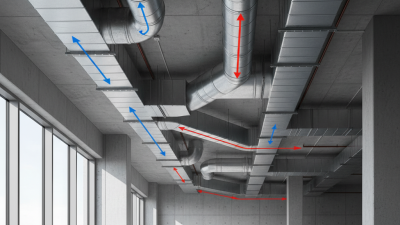

In addition to their practical applications, copper elbow fittings are often employed in various specific plumbing configurations. For example, they can be found in heating systems where they facilitate the movement of hot water through radiators or baseboards. Similarly, in drainage systems, these fittings help manage the flow of wastewater, preventing clogs and ensuring proper disposal. Their versatility extends to outdoor irrigation systems as well, where they aid in directing water to specific areas of gardens or lawns. Overall, the use of copper elbow fittings in plumbing systems enhances functionality and contributes to the longevity and efficiency of the entire infrastructure.

This chart illustrates the various applications of copper elbow fittings in plumbing systems, highlighting their significance in different plumbing scenarios.

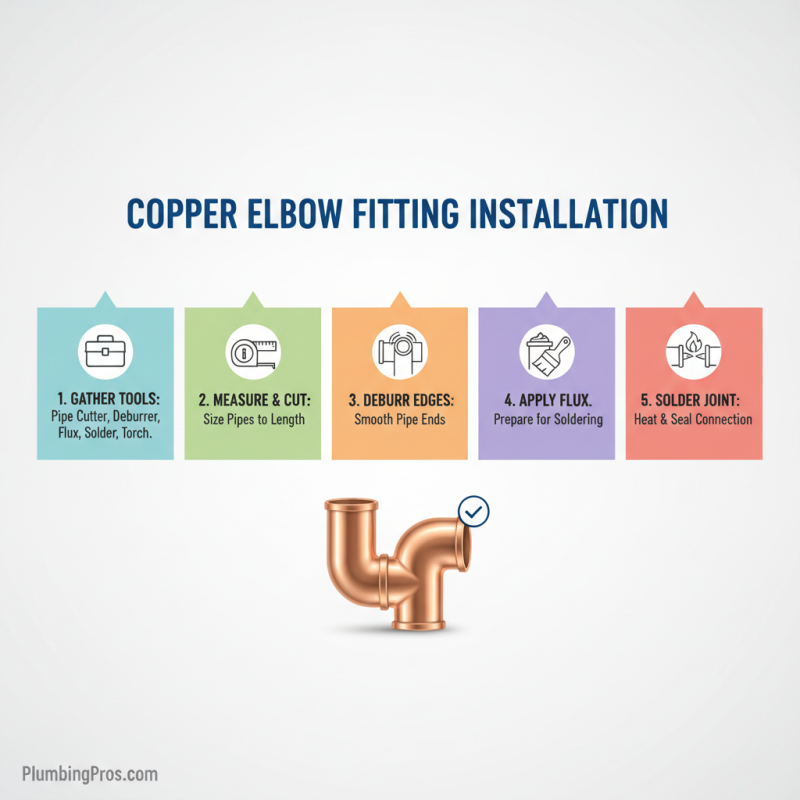

The installation process of copper elbow fittings is a crucial aspect of setting up efficient plumbing systems. To begin with, it is essential to gather the necessary tools, which typically include a pipe cutter, a deburring tool, flux, solder, and a propane torch. Once the tools are ready, the first step involves measuring and cutting the copper pipes to the required lengths. After cutting, one must use a deburring tool to smooth the edges of the pipes, which helps to ensure a proper fit and reduces the risk of leaks.

Next, the installation of the copper elbow fitting begins. The cut ends of the pipes are thoroughly cleaned and then coated with flux to promote better soldering. The elbow fitting is slid onto one end of the pipe, aligning it according to the planned angle for the plumbing layout. The other pipe end is then connected to the fitting in the same manner. With the connections in place, a propane torch is used to heat the solder around the joints, allowing it to flow and create a watertight seal. It is important to allow the solder to cool naturally before testing the system for leaks, ensuring a secure and durable plumbing installation.

Copper elbow fittings are essential components in plumbing systems, allowing pipes to change direction efficiently. Proper maintenance and care are crucial to ensure their longevity and functionality. Over time, copper fittings can develop issues such as corrosion or buildup of deposits that may restrict water flow. To keep these fittings in optimal condition, regular inspections and cleaning are recommended.

To maintain your copper elbow fittings, ensure you periodically check for signs of wear, such as discoloration or build-up of mineral deposits. If any issues are detected, cleaning can usually be accomplished using a gentle vinegar solution that helps dissolve any minerals without damaging the copper. Additionally, applying a thin layer of plumber's grease on the threads can help prevent corrosion when connecting with other plumbing components.

**Tips:** Avoid using abrasive cleaners or materials when working with copper fittings, as they can scratch and damage the surface. Instead, opt for soft cloths or sponges. Furthermore, consider investing in water softeners if you live in an area with hard water; this can significantly reduce mineral buildup in your plumbing system. Regular maintenance not only extends the life of your fittings but also ensures a smooth plumbing operation overall.