When selecting adjustable PVC elbow fittings, many factors come into play. The choice can greatly affect efficiency and durability in piping systems. A recent industry report by the Plastics Pipe Institute reveals that 75% of piping failures stem from improper fittings. This underscores the need for careful selection.

According to industry expert Dr. Jane Rogers, “The right adjustable PVC elbow can enhance flow and extend the life of your system.” It is crucial to consider the dimensions and angles during your selection process. A fitting that does not conform to specifications can lead to leaks and costly repairs.

In today's market, the availability of various adjustable PVC elbow options can be overwhelming. Balancing quality with cost is essential. Many consumers overlook the importance of proper fittings and make hurried decisions. Thus, understanding these critical components is vital for achieving optimal performance.

Adjustable PVC elbow fittings play a crucial role in plumbing, HVAC, and irrigation systems. Their primary function is to change the direction of flow smoothly. This flexibility is essential for maintaining efficiency in various applications. According to industry reports, proper fitting selections can reduce energy loss by up to 15%. This statistic emphasizes the importance of choosing the right elbows carefully.

When selecting adjustable PVC elbow fittings, consider the bend radius. A good bend radius minimizes friction loss. Sharp bends can disrupt flow, leading to pressure drops. It's essential to balance between available space and flow efficiency. Sometimes, it’s tempting to opt for cheaper options; however, this could result in higher maintenance costs down the line. Look for fittings that offer durability without compromising performance.

Fit your project needs. Measure all dimensions accurately before purchasing. Many overlook the importance of size. Using the wrong size can lead to fitting failures. It's also wise to consider temperature and pressure ratings. These factors determine the longevity of the fittings in your system. Don't rush this part of your project; decisions made in haste can lead to costly mistakes later.

When selecting adjustable PVC elbow fittings, size and angle are crucial. A poor choice can lead to leaks or blockages. To begin, measure the diameter of your existing pipes. This ensures a snug fit. Consider the angle carefully. A 45-degree angle may work better in tight spaces than a 90-degree angle. Each angle impacts flow rate differently.

One common mistake is not accounting for future adjustments. The fitting should allow flexibility. A well-chosen elbow can save you time in the long run. Always visualize how the fitting will connect within your system. Picture pipe placement and potential bends. This helps in avoiding awkward joints or unexpected restrictions.

Don’t forget about wall thickness. Thicker walls typically offer more durability. However, ensure they fit the same size requirements. Lastly, trust your instincts. If something feels off about your choice, it probably is. Remember, it’s better to rethink than face complications later. Stay thoughtful in your selection process.

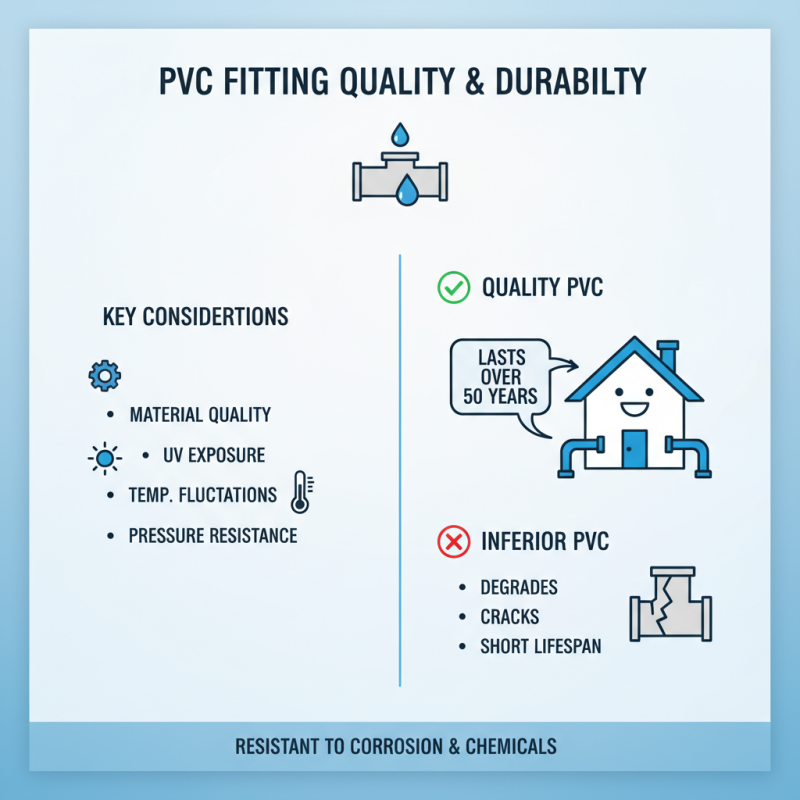

When evaluating the material quality and durability of PVC fittings, it's crucial to consider several factors. PVC (Polyvinyl Chloride) is a widely used material in plumbing due to its resistance to corrosion and chemical damage. According to a recent industry report, quality PVC can last over 50 years in various applications. However, not all PVC is created equal. Inferior products may degrade or crack under UV exposure, temperature fluctuations, or pressure.

Tip 1: Check for certification marks. Certified products meet specific standards, ensuring they withstand normal wear and tear. Look for markings from reputable associations.

Notably, the manufacturing process also impacts durability. Some fittings may include fillers that weaken the structure. Only choose fittings from reputable manufacturers that disclose their production processes. Scrutinizing material composition is critical. Pure PVC should have minimal additives.

Tip 2: Conduct a flexibility test. This simple test can identify more brittle fittings. Bend the elbow fitting slightly; if it breaks easily, it's likely not high-quality.

Environmental factors also play a role in the lifespan of PVC fittings. Exposure to extreme temperatures can lead to brittleness. Consider the climate where the fittings will be installed. A fitting that performs well in one environment might not in another.

Tip 3: Examine the warranty. A longer warranty usually indicates manufacturer confidence in product durability. If there’s no warranty, question the quality.

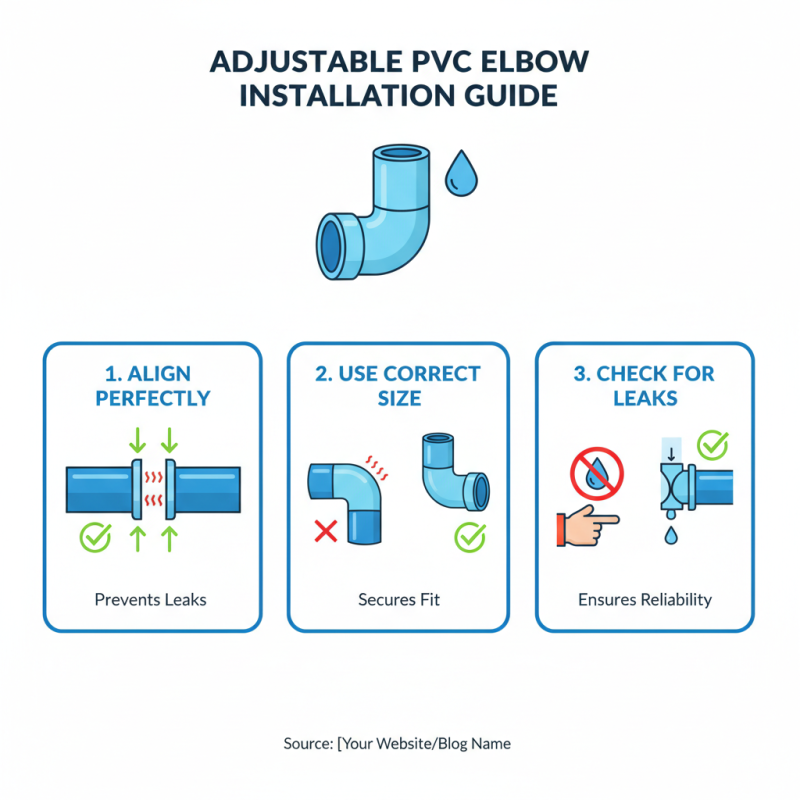

When installing adjustable PVC elbow fittings, focus on proper installation to prevent leaks. Ensure that the fitting aligns perfectly with the pipes. Misalignment can cause significant leakage. Check that the elbow is the right size for your setup. A loose fit may not seal correctly, leading to problems later on.

Use solvent cement as directed. Applying too much or too little can lead to a weak bond. Allow adequate time for the cement to cure before pressurizing the system. A rushed installation often results in unexpected leaks. This caution should not be overlooked.

Check all connections thoroughly after installation. Just because it looks secure does not mean it is leak-proof. Regular inspections are essential, especially after initial use. Address any sign of moisture immediately. Ignoring small leaks can lead to larger issues down the road, making preventive measures crucial.

When considering adjustable PVC elbow fittings, comparing different brands and manufacturers is crucial. The market offers various options, each with distinct features. According to a report by the Construction Industry Institute, product performance varies widely among manufacturers, impacting durability and flexibility.

Many brands do not invest equally in technology and quality control. Some manufacturers cut costs, leading to variations in material strength. A survey indicated that about 30% of users experienced leakage with lower-end products. This statistic highlights the importance of selecting reliable brands that prioritize quality in their manufacturing processes.

Understanding the specifications of fittings can guide you in making the right choice. Look for certifications and laboratory testing results. Not every brand offers transparent information about their products. In fact, nearly 40% of buyers reported being uncertain about the technical details of the fittings they purchased. This ambiguity can lead to frustrations and unexpected issues during installation.

Consider tracking trends in customer reviews, as they often reflect real-world performance over time.