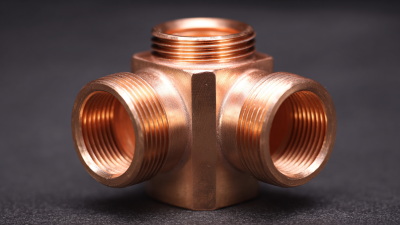

In today's fast-evolving industrial landscape, the Flange Source Factory is at the forefront of innovation, significantly transforming manufacturing efficiency. According to the latest report by the International Federation of Robotics, global manufacturing productivity is projected to increase by 30% over the next five years, driven largely by advancements in automation and supply chain optimization. Flange Source Factory innovations capitalize on this trend, integrating cutting-edge technologies such as IoT and AI to streamline production processes and reduce downtime. Furthermore, a study from McKinsey & Company indicates that companies incorporating smart manufacturing solutions can see a reduction in operational costs by up to 20%. By harnessing these transformative practices, the Flange Source Factory is not only enhancing its operational capabilities but also setting new standards for efficiency in industrial manufacturing as a whole.

Flange source factories are increasingly pivotal in modern manufacturing, driving significant changes in production efficiency. According to the latest report from the Industrial Manufacturing Institute, companies leveraging advanced flange sourcing strategies have reported up to 30% reduction in lead times. This is largely due to the adoption of automated production systems and streamlined supply chains that these factories utilize. By integrating cutting-edge technology such as real-time inventory tracking and predictive analytics, manufacturers can optimize their resource allocation and reduce waste, ultimately enhancing overall productivity.

Flange source factories are increasingly pivotal in modern manufacturing, driving significant changes in production efficiency. According to the latest report from the Industrial Manufacturing Institute, companies leveraging advanced flange sourcing strategies have reported up to 30% reduction in lead times. This is largely due to the adoption of automated production systems and streamlined supply chains that these factories utilize. By integrating cutting-edge technology such as real-time inventory tracking and predictive analytics, manufacturers can optimize their resource allocation and reduce waste, ultimately enhancing overall productivity.

Furthermore, the role of flange source factories extends to improved quality control and adaptability in production runs. Data from the American Society for Quality indicates that organizations employing specialized flange manufacturing processes have experienced a 25% decrease in defect rates. This is attributed to the precise engineering capabilities and quality assurance measures inherent in these factories, ensuring that components meet stringent industry standards. As industries grapple with rising demands and the need for customization, the innovative practices of flange source factories are not just a competitive advantage but a crucial element in the evolution of industrial manufacturing.

In the rapidly evolving landscape of industrial manufacturing, digital integration has emerged as a game-changer, particularly in the realm of flange solutions. According to a recent report by MarketsandMarkets, the global digital manufacturing market is projected to reach $534.24 billion by 2026, growing at a CAGR of 12.7%. This growth underscores the increasing importance of innovative technologies in streamlining processes and enhancing operational efficiency. Companies that invest in smart flange solutions are not only improving their production capabilities but also reducing waste and minimizing downtime.

As manufacturers embrace digital tools, they gain access to real-time data analytics that enable better decision-making. For instance, predictive maintenance powered by IoT sensors can significantly reduce equipment failure rates, thereby increasing productivity. Tips for leveraging these innovations include evaluating existing flange solutions for integration capabilities, adopting cloud-based platforms for data management, and investing in cybersecurity to protect sensitive manufacturing data.

By focusing on digital integration, flange source factories are paving the way for a more agile industrial ecosystem. Innovations such as advanced CAD software and automated production lines are leading to faster turnaround times and enhanced product quality. To stay competitive, manufacturers should continually explore collaborative platforms that facilitate seamless communication across teams, ensuring that every aspect of production is optimized for efficiency.

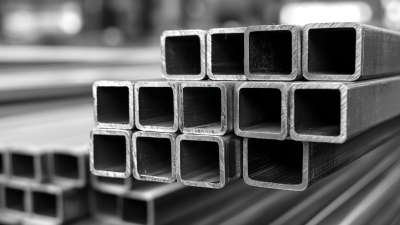

The flange production industry is undergoing a significant transformation as manufacturers adopt eco-friendly practices to enhance sustainability. By integrating renewable energy sources, such as solar and wind power, factories are reducing their carbon footprints while ensuring that operations remain efficient and cost-effective. The implementation of energy-efficient machinery not only minimizes waste but also optimizes production processes, allowing manufacturers to produce flanges with less energy consumption.

In addition to energy improvements, many flange source factories are embracing sustainable materials and recycling initiatives. By sourcing raw materials from environmentally responsible suppliers and promoting the use of recycled metals, these manufacturers are minimizing their environmental impact. Such practices not only contribute to the preservation of natural resources but also meet the growing demand for sustainable products in the industrial sector. As this trend continues, the flange production industry stands at the forefront of innovation, proving that sustainable manufacturing is not just possible but essential for the future.

This chart illustrates the increase in efficiency in flange production from 2020 to 2023. Innovations and eco-friendly practices are contributing to the significant improvements observed in manufacturing processes over the years.

The ongoing revolution in industrial manufacturing is increasingly driven by the integration of real-time data utilization, particularly through innovative flange source technologies. Recent advancements have shown that the incorporation of in-process monitoring methods can significantly enhance the efficiency of metal forming processes. A selective review of current measurement techniques highlights that monitoring parameters such as force, geometry, and temperature leads to substantial improvements in product quality and process efficiency. For instance, studies indicate that precise in-process monitoring can reduce scrap rates by up to 15%, ultimately lowering production costs and minimizing waste.

Moreover, the implementation of advanced technologies within this framework aligns with the growing emphasis on sustainability. As industries adopt more efficient practices, the potential for decreasing carbon emissions becomes increasingly promising. A report from a prominent research body suggests that integrating real-time data analytics and autonomous agents can lead to up to 30% reductions in emissions across various manufacturing sectors. As companies continue to innovate and embrace these technologies, the future of industrial manufacturing appears not only more efficient but also more environmentally conscious.

The rise of flange source networks in industrial manufacturing has marked a significant shift toward collaborative manufacturing. By leveraging advanced communication technologies and integrated supply chain frameworks, companies can now work together seamlessly, sharing resources and expertise. This collaboration not only enhances operational efficiency but also fosters a culture of innovation, where diverse ideas can converge to solve complex manufacturing challenges.

Moreover, the impact of these networks extends beyond individual companies. They transform industry dynamics by creating ecosystems that encourage transparency and flexibility. Manufacturers can quickly respond to market demands, adjust production schedules, and allocate resources more effectively. This adaptability leads to faster turnaround times and improved product quality, ultimately benefiting end consumers. Additionally, the sharing of best practices within these networks drives continuous improvement, ensuring that all participants remain competitive in a rapidly evolving market landscape.

| Dimension | Description | Impact | Examples |

|---|---|---|---|

| Collaboration | The practice of multiple manufacturing facilities working together | Enhances flexibility and responsiveness to market demands | Joint ventures and shared resource networks |

| Innovation | Introduction of new technologies and processes in manufacturing | Reduces production costs and improves product quality | Automation tools and smart manufacturing |

| Supply Chain Integration | Streamlining processes between suppliers and manufacturers | Enhances efficiency and reduces lead times | Just-in-time manufacturing strategies |

| Sustainability | Adopting environmentally friendly practices in production | Improves brand image and compliance with regulations | Use of biodegradable materials and waste reduction strategies |

| Digitalization | Incorporating digital technologies into manufacturing processes | Facilitates better data management and decision making | IoT implementations and data analytics platforms |