In the realm of home safety and energy efficiency, the design and maintenance of dryer vent systems play an indispensable role. Recent statistics indicate that malfunctioning or improperly installed dryer vents, including critical components like the Elbow For Dryer Vent, contribute to an estimated 15,000 house fires annually in the United States, according to the National Fire Protection Association (NFPA). These incidents not only pose significant safety risks but also lead to energy inefficiencies that can inflate utility bills.

The Elbow For Dryer Vent, specifically, is vital for maintaining optimal airflow and reducing lint accumulation, which can drastically minimize fire hazards. By understanding the importance of proper vent design and implementing essential strategies for maximization, homeowners can significantly enhance dryer efficiency while safeguarding their families and properties from potential fire dangers.

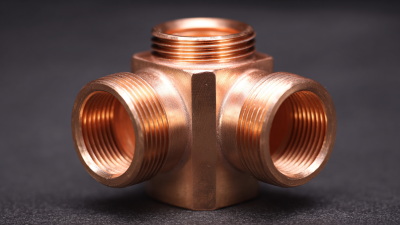

Proper dryer vent elbow design is essential in preventing fire hazards associated with household dryers. The elbows in dryer vent systems are crucial because they direct the flow of moist air and lint away from the dryer and outside of the house. If these elbows are poorly designed or installed at sharp angles, they can trap lint and prevent it from fully exiting the system. This accumulation of lint not only restricts airflow but also poses a significant fire risk, as lint is highly flammable.

Moreover, the use of high-quality materials and appropriate angles in the vent elbow design can greatly enhance dryer efficiency. When the vent is properly configured, it allows for smooth airflow, reducing the drying time and energy consumption of the dryer. In contrast, a poorly designed elbow can lead to increased drying times, which results in higher energy bills and a greater likelihood of overheating. Therefore, investing in the right dryer vent elbow design is not only a safety measure to prevent fires but also a critical step in optimizing the dryer’s performance.

This chart illustrates the correlation between proper dryer vent elbow angles and the frequency of dryer fires. The data emphasizes that vent angles closer to the recommended 90 degrees result in a lower incidence of fire hazards.

Clothes dryers are a common household appliance, yet they pose significant fire risks if not properly maintained. A statistical analysis reveals that many dryer-related fires stem from venting issues, particularly those associated with improper airflow. One critical component in this system is the elbow of the dryer vent, which can become a trap for lint and debris if not regularly cleaned. This buildup not only obstructs efficient airflow but also creates a highly flammable environment.

To mitigate these risks, homeowners should prioritize regular maintenance of their dryer vents, alongside best practices like cleaning the lint screen after every load. Such preventive measures are essential not just for fire safety, but also for enhancing dryer efficiency. By ensuring that the venting system is clear, individuals can significantly reduce the likelihood of ignition, contributing to a safer home overall. Regular inspections and cleanings can help homeowners stay ahead of potential hazards, turning their attention toward a straightforward yet often overlooked aspect of household safety.

When it comes to maximizing dryer efficiency, the angle of the elbow in the dryer vent plays a critical role in maintaining optimal airflow. A well-placed elbow allows for a smoother transition of air, which is essential in reducing lint buildup. Generally, a 45-degree angle is ideal; it strikes a balance between minimal airflow resistance and effective lint expulsion. This angle helps maintain a strong airflow, ensuring that moisture exits efficiently while minimizing the possibility of lint accumulating in the vent.

Tips for effective dryer vent installation include ensuring that the vent is as short and straight as possible. Fewer bends mean less obstruction, which further enhances airflow. If bends are necessary, opting for an elbow with a larger radius can also help maintain airflow integrity. Regularly inspecting and cleaning the vent connections will prevent lint buildup, which is a significant fire hazard.

Implementing these strategies not only promotes dryer efficiency but also ensures that your appliance operates safely. By optimizing the elbow angles and maintaining cleanliness in your dryer vent system, you are taking essential steps towards a safer and more efficient laundry routine.

When it comes to dryer vent installation and maintenance, adhering to industry guidelines is essential for maximizing efficiency and minimizing fire hazards. One critical component in this system is the elbow fitting, which aids in directing airflow. Improper installation or maintenance of these vents can lead to lint buildup, reducing airflow and creating potential fire risks. Regular inspection is necessary to ensure that these fittings are clear and functioning efficiently, as stagnant air can lead to overheating and potential fires.

Tips for maintaining your dryer vent include scheduling regular cleanings, which can often be a straightforward DIY task. You can effectively use tools like a toilet brush to remove any lint clogs from the exterior vent. Additionally, make sure to check the outside dryer vent for any debris caused by outdoor humidity. Keeping this area clear will enhance airflow and further reduce fire risks.

Moreover, staying informed about fire code requirements is vital. Ensure that your setup meets regulations, especially those pertaining to heating appliances. Compliance not only promotes safety but also enhances the efficiency of your drying appliances. Regular maintenance checks for both the internal and external components will ensure optimal performance, protecting your home from potential hazards.

The efficiency and safety of dryer systems are significantly influenced by the type and length of the vent used. A critical component, the elbow in a dryer vent, plays a key role in ensuring that airflow remains unobstructed. Long or improperly configured vents can lead to increased resistance, resulting in longer drying times and overworking the dryer. This not only decreases energy efficiency but also poses a heightened fire risk as lint accumulates in areas that are harder to clean.

Selecting the right type of vent material is equally important. Smooth, rigid ducting is often recommended over flexible ducting, as it minimizes lint buildup and facilitates better airflow. Additionally, the overall length of the vent should be kept to a minimum; longer vents can create dead spots where lint can gather and potentially ignite. Regular maintenance, including cleaning out the vent and checking for damage, further enhances safety and efficiency, ultimately providing peace of mind while using household dryers.