In the world of HVAC systems, a Rectangular Duct Elbow plays a crucial role. According to John Smith, a renowned expert in airflow dynamics, “The efficiency of an HVAC system often hinges on the quality of ductwork, particularly at bends.” This highlights the importance of a well-designed Rectangular Duct Elbow in maintaining airflow efficiency.

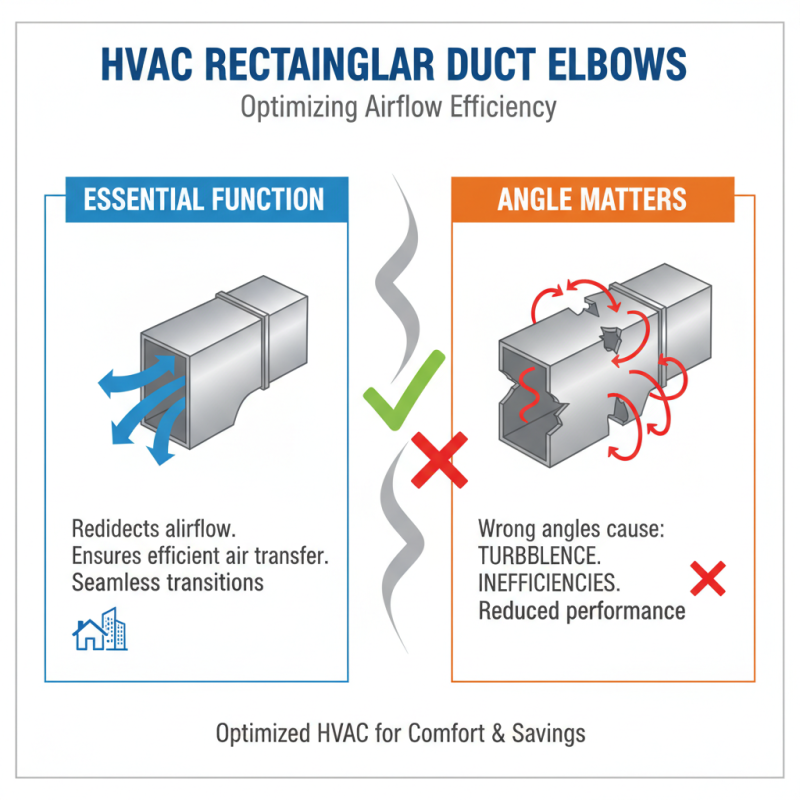

Rectangular Duct Elbows are used to change the direction of air traveling through ducts. This design minimizes turbulence, which is essential for optimal airflow. Poorly designed elbows can lead to reduced system performance. Smith further emphasizes, “Every angle in ductwork can impact energy use and indoor air quality.” When the right angles are not used, air can become stagnant.

Understanding Rectangular Duct Elbows is vital for anyone involved in HVAC design and installation. With increasing energy costs, the need for efficient systems is more pressing than ever. Thus, a thoughtful examination of duct design is necessary for both performance and sustainability. Balancing functionality with efficiency can be challenging, but essential.

A rectangular duct elbow is a crucial component in HVAC systems. It is designed to change the direction of airflow within ductwork. Typically made from sheet metal or other durable materials, the elbow allows for 90-degree or 45-degree turns. Its shape helps minimize air resistance, ensuring efficient airflow.

Understanding how a rectangular duct elbow works is essential. When air flows through a straight duct, it moves uniformly. However, when it reaches an elbow, the air needs to navigate the bend. This can create turbulence, which may reduce efficiency. Some elbows are designed with smoother curves to help mitigate these effects. If not properly installed, it can lead to issues like reduced airflow or increased noise.

In practice, rectangular duct elbows can be used in various applications. They are often found in commercial buildings, homes, and industrial settings. Their placement must be carefully considered. Improper positioning can result in increased energy costs. Choosing the right angle and size matters. Each application is unique, demanding custom solutions that might not always be apparent at first glance.

Rectangular duct elbows are essential in HVAC systems. They help redirect airflow in various directions. This ensures the efficient transfer of air in residential and commercial spaces. The design allows for seamless transitions. However, the wrong angle can lead to turbulence and inefficiencies.

There are several types of rectangular duct elbows. The 45-degree elbow is common for gentle turns. It helps maintain airflow speed while redirecting the path. The 90-degree elbow is great for sharp turns but may cause issues. Increased pressure drop can lead to higher energy costs.

Applications vary widely. In industrial settings, elbows connect main ducts to machinery. In homes, they lead air to vents efficiently. However, improper installation can cause noise and reduced airflow. It's vital to select the proper type for the application. Different angles can drastically change performance and efficiency. Exploring options is necessary to achieve the best results.

Rectangular duct elbows are key components in HVAC systems. They allow the ductwork to change direction, which enhances air circulation. With these elbows, airflow can smoothly navigate corners and avoid unnecessary resistance. This promotes efficient heating and cooling throughout a building. When duct systems are well-designed, every space receives the right amount of air.

Using rectangular duct elbows offers several benefits. They help optimize airflow, reducing energy loss. Improved air distribution can lead to better indoor air quality. However, improper installation or sizing can lead to inefficiencies. No one wants uneven heating or cooling. It's vital to pay attention to measurements to ensure effectiveness.

Incorporating these elbows into a duct system also aids in space management. They fit well in tight areas while maintaining functionality. However, not all elbows are created equal. The flow dynamics can vary significantly. Evaluating the specific needs of each project is crucial. This careful consideration can yield the best performance in HVAC systems.

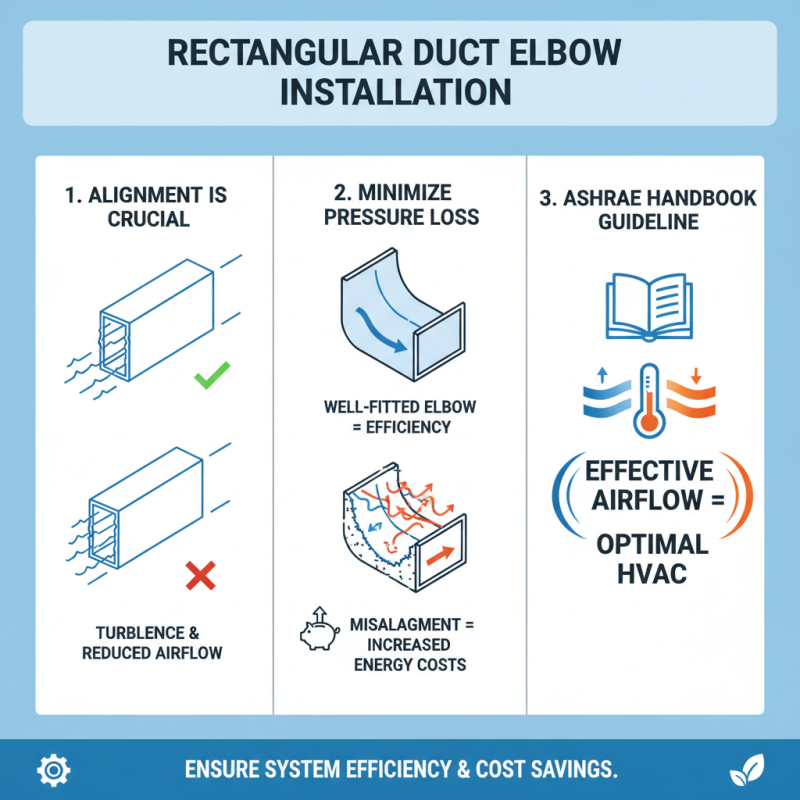

Installation considerations for rectangular duct elbows are crucial for ensuring system efficiency. Proper alignment is vital. Misalignment can create turbulence, reducing airflow. According to the ASHRAE Handbook, effective airflow is essential for heating and cooling systems. A well-fitted elbow minimizes pressure loss, which can otherwise lead to increased energy costs.

When installing these components, proper support is needed. Duct elbows should be secured to prevent sagging. A sagging duct can lead to joint leaks and wasted energy. The industry standard suggests spacing supports every 5 to 10 feet in straight runs. Such measures can enhance performance and longevity.

Moreover, it's essential to consider the angle of the elbow. Standard angles are 30, 45, or 90 degrees. Each angle affects airflow differently. A 90-degree elbow typically incurs more system resistance, which can lower efficiency. For a balanced system, consider the layout. An efficient design can ultimately improve air distribution. Balancing aesthetics with functionality is often challenging yet necessary.

Rectangular duct elbows are essential components in HVAC systems, allowing airflow to change direction. However, they can pose several challenges that affect system efficiency and performance. One common issue is airflow resistance. Studies indicate that improper design can lead to a pressure drop of over 30% in some systems, which can be detrimental to energy efficiency.

Another issue is noise. Turns in the ductwork often amplify sound, leading to an uncomfortable environment. This can be especially problematic in residential settings. According to a report from the Acoustic Society, noise levels can increase by 10 dB when air flows through sharp elbows. Addressing these issues can improve both performance and comfort.

Tips: Ensure smooth transitions in duct elbows. This minimizes turbulence and reduces noise. Regularly inspect and maintain the ductwork to prevent airflow blockages. Unnecessary bends should be avoided to maintain system integrity. Rectangular elbows should be installed at the right angle to prevent stress on the system.