The global flange manufacturing market plays a crucial role in enhancing various industrial applications, from oil and gas to water distribution systems. As per a recent market analysis report by Mordor Intelligence, the flange market is projected to reach an estimated value of over $10 billion by 2026, growing at a CAGR of approximately 5.6%. This growth reflects the increasing demand for durable and reliable piping connections that flange manufacturers provide.

Flange manufacturers are not just suppliers; they are pivotal contributors to ensuring structural integrity and safety in critical systems. By leveraging advanced materials and adhering to strict industry standards, these manufacturers help optimize performance and minimize failures in piping systems. In an era of industrial innovation, understanding the role of flange manufacturers becomes essential for anyone involved in the modern industrial landscape.

Flanges play a critical role in modern industrial infrastructure, acting as vital components in the construction of piping systems across various sectors. According to a report by MarketsandMarkets, the global flange market is projected to reach over $18 billion by 2025, driven by the increasing demand for efficient fluid handling systems in the oil and gas, petrochemical, and power generation industries. Flanges facilitate seamless connections and disconnection of piping systems, ensuring safety and reliability in conveying fluids and gases under high pressure and temperature conditions.

In addition to their functional benefits, flanges significantly contribute to operational efficiency. A study from the American Society of Mechanical Engineers (ASME) indicates that improper flange design or installation can lead to significant leaks and system failures, resulting in costs that can reach millions in repairs and lost production. Effective flange solutions not only enhance safety and performance but also adhere to stringent regulatory standards, making them essential for sustained industrial success.

As industries continue to evolve, the importance of durable and reliable flange systems will only increase, underscoring the crucial role of flange manufacturers in providing innovative and effective solutions for varied applications.

When selecting the right flange manufacturer for your industrial needs, several key factors come into play. Quality assurance is paramount; according to a report by Market Research Future, the global flange market is expected to reach USD 10 billion by 2028, underscoring the importance of reliable manufacturing processes. Look for manufacturers that adhere to international standards such as ASTM, ASME, or API, which ensure that the flanges meet stringent quality and performance criteria. These standards can be a strong indicator of a manufacturer’s commitment to excellence and consistency.

In addition to quality, the manufacturer's ability to customize solutions is crucial. With diverse applications across industries such as oil and gas, aerospace, and water treatment, one-size-fits-all solutions can often fall short. A study published in the Journal of Manufacturing Science and Engineering revealed that customized flanges can enhance efficiency and reduce failure rates by up to 30%. Therefore, partnering with a manufacturer that offers tailored designs and materials can lead to significant operational benefits. Furthermore, consider their customer support and experience; manufacturers with a proven track record in your specific industry will likely better understand your needs and challenges.

Flanges play a critical role in various industrial applications, serving as crucial connecting components in piping systems. Understanding different types of flanges and their specific uses can significantly enhance operational efficiency and safety. Common types include welded neck flanges, which provide strength in high-pressure applications; slip-on flanges, known for ease of installation; and blind flanges, designed to seal the ends of pipes when a connection isn't required. Each type serves a distinct purpose based on the demands of the particular application, such as temperature, pressure, and the nature of the fluid being transported.

Flanges play a critical role in various industrial applications, serving as crucial connecting components in piping systems. Understanding different types of flanges and their specific uses can significantly enhance operational efficiency and safety. Common types include welded neck flanges, which provide strength in high-pressure applications; slip-on flanges, known for ease of installation; and blind flanges, designed to seal the ends of pipes when a connection isn't required. Each type serves a distinct purpose based on the demands of the particular application, such as temperature, pressure, and the nature of the fluid being transported.

When selecting flanges, it’s essential to consider both material compatibility and the specific requirements of your project. Always check for proper specifications such as pressure ratings and material certifications. Tips: Ensure that you consult with your flange manufacturer to determine the best type for your needs, and don’t hesitate to ask for recommendations based on your operational environment.

In addition to choosing the right type, maintaining flanges is crucial to ensure long-term integrity and performance. Regularly inspect for corrosion, leaks, and misalignment, especially in stringent applications. Tips: Implement a routine maintenance schedule and train staff in basic inspection techniques to prevent costly downtime and ensure safety.

In modern industrial applications, the role of flange manufacturers is pivotal, particularly when it comes to adhering to stringent quality control standards. These manufacturers play a crucial role in ensuring the integrity and safety of piping systems across various sectors, including oil and gas, power generation, and chemical processing. According to a report by the American Society of Mechanical Engineers (ASME), approximately 70% of industrial accidents are linked to failures in piping systems, highlighting the necessity of quality assurance in flange production.

Quality control in flange manufacturing encompasses several critical processes, including material selection, dimensional accuracy, and surface finish. A study published in the Journal of Manufacturing Science and Engineering indicates that flanges produced under rigorous quality control protocols exhibit a 30% increase in longevity and performance reliability. ISO 9001 certification and adherence to ASTM standards are essential benchmarks that flange manufacturers must meet to ensure their products can withstand the demanding conditions of modern applications. By implementing these quality control measures, manufacturers can significantly reduce the risk of failures and enhance overall system reliability, thereby contributing to safer operations across various industries.

| Parameter | Description | Quality Control Standard | Inspection Method |

|---|---|---|---|

| Material Composition | Analysis of raw materials used in flange manufacturing. | ASTM A105 and other relevant standards. | Spectroscopic analysis. |

| Dimensional Accuracy | Measurement of flange size and shape according to specifications. | ISO 2768 | Calipers and laser measurement tools. |

| Surface Finish | Assessment of surface roughness and coatings. | ISO 1302 | Roughness measurement instruments. |

| Mechanical Properties | Testing of tensile strength, yield strength, and hardness. | ASTM E8/E8M | Tensile testing machines. |

| Weld Quality | Evaluation of weld integrity and discontinuities. | AWS D1.1 | Visual inspection and X-ray testing. |

The flange manufacturing industry is poised for significant advancements, driven by the increasing demands of modern applications across sectors such as oil and gas, construction, and aerospace. According to a recent market analysis, the global flanges market is expected to grow at a CAGR of 4.5% from 2022 to 2028, largely fueled by innovations such as lightweight materials and enhanced manufacturing processes. More specifically, the incorporation of advanced materials like carbon fiber and composites is changing the landscape, leading to flanges that offer improved durability and corrosion resistance, crucial for harsh operational environments.

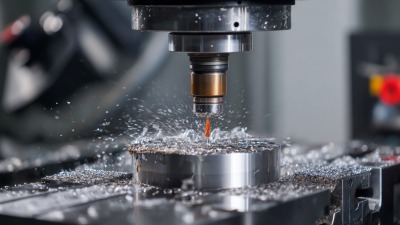

Additionally, the integration of Industry 4.0 technologies is revolutionizing flange manufacturing. Automated production lines, enabled by robotics and smart sensors, are enhancing efficiency and precision while reducing downtime. Recent reports indicate that companies implementing these technologies have seen productivity improvements of up to 30%. Furthermore, additive manufacturing techniques, such as 3D printing, are emerging as game-changers, allowing for customization and rapid prototyping. This innovation not only reduces lead times but also supports sustainability efforts by minimizing waste, making the future of flange manufacturing more efficient and environmentally friendly.