Choosing the right Seamless Boiler Tubes is crucial for optimizing performance in industrial settings. According to John Smith, a renowned expert in the boiler industry, "The right choice can significantly improve efficiency and safety." Seamless Boiler Tubes offer numerous advantages over welded options, such as enhanced strength and reliability. However, selecting the correct type requires careful consideration.

When evaluating Seamless Boiler Tubes, factors like material composition, diameter, and wall thickness must be assessed. Each choice impacts performance differently. Remember, what works for one application may not suit another. Ensuring the right specifications is essential to minimize future issues.

In an ever-evolving industry, there’s little room for mistakes. Relying solely on experience can lead to oversight. It’s important to keep abreast of advancements and standards. Seamless Boiler Tubes may seem straightforward, but each installation is unique. Reflecting on these complexities can make all the difference in achieving optimal outcomes.

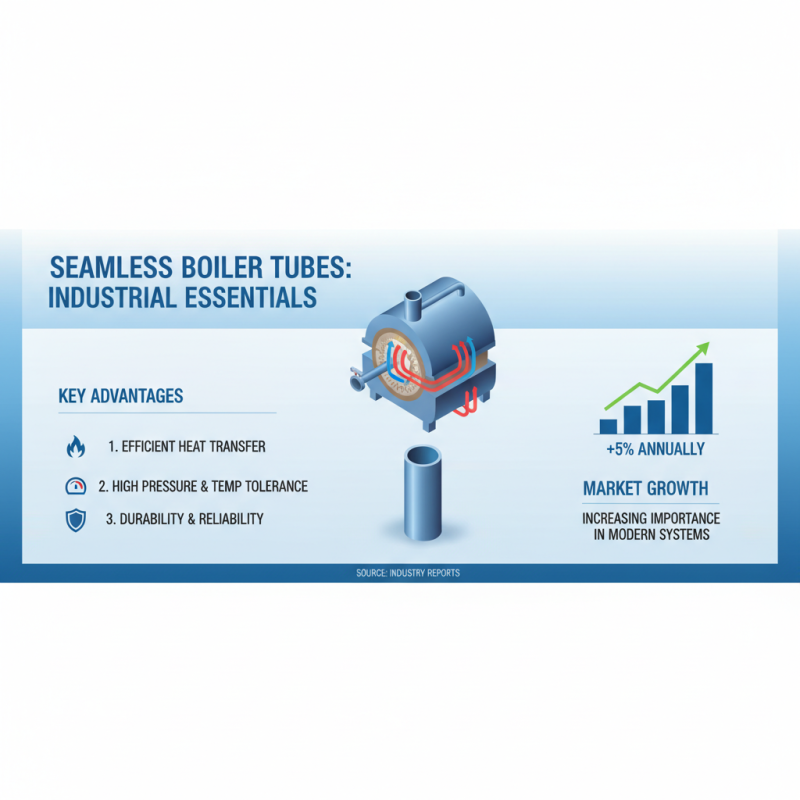

Seamless boiler tubes play a crucial role in various industrial applications. These tubes are essential for transferring heat efficiently within boiler systems. Their seamless nature allows for higher pressure and temperature tolerance. According to industry reports, the market for seamless tubes is projected to grow by 5% annually, reflecting their increasing importance in modern systems.

When selecting seamless boiler tubes, consider material composition and size. Carbon steel and alloy steel are popular choices. Each material offers unique advantages. For instance, carbon steel provides good strength but may not withstand high temperatures as well as alloy steel. Always evaluate the specific needs of your boiler system before making a decision.

Tip: Ensure to check the manufacturing standards. Quality assurance is vital. Tubes must meet international specifications for safety and performance. This can prevent costly failures in the long run.

Another essential aspect is the proper installation technique. A poorly installed tube can lead to leaks and inefficiencies. This may compromise the entire boiler operation. Regular inspections can help detect issues early.

Tip: Keep an eye on industry trends and advancements. This knowledge can influence your choices. Upgrading materials and technologies may enhance efficiency and performance.

When selecting seamless boiler tubes, several key factors come into play. Material composition is critical; it affects durability and performance. High-quality carbon steel is often preferred. This material can withstand extreme temperatures and pressures. According to industry reports, seamless tubes can last up to 30% longer than welded alternatives under similar conditions.

Wall thickness is also essential. It impacts heat transfer efficiency and resistance to corrosion. A tube with a thickness of at least 10 mm is generally recommended for high-pressure applications. However, thicker walls can increase weight. This trade-off can complicate installation.

The manufacturing process matters too. Tubes produced using rotary pierce methods often exhibit better structural integrity. Some studies indicate that improperly finished seams can lead to premature failures. It’s crucial to inspect for any defects. Inadequate attention to these details may lead to significant safety risks over time. An informed, cautious approach can yield better long-term results in boiler tube performance.

Choosing the right material for seamless boiler tubes is crucial for performance. Steel grades play a significant role in this decision. Common materials include carbon steel, alloy steel, and stainless steel. Each has its benefits and drawbacks.

Carbon steel is often a cost-effective choice. It offers good tensile strength, making it suitable for various applications. However, it may not perform well under extreme temperatures. This can lead to a need for early replacements. Alloy steel, enriched with elements like chromium and molybdenum, enhances durability. It's more resistant to corrosion and wear, but it can be pricier.

Stainless steel combines corrosion resistance with high strength. This makes it ideal for harsh environments. Yet, the cost may limit its use in some projects. Considering these factors can be overwhelming. Careful evaluation of each grade is essential for a successful choice. Reflection on specific project needs can help guide this decision.

When selecting seamless boiler tubes, understanding the manufacturing process is vital for ensuring quality assurance. The method used to produce these tubes has a direct impact on their mechanical properties. For example, processes like extruding and rotary piercing are commonly utilized. Each step matters. Focusing on the integrity of the materials can prevent future failures.

Tips for choosing seamless boiler tubes include checking the heat treatment processes. Heat treatment enhances the strength and durability of the tubes. Make sure the manufacturer uses precise controls during this stage. Inquire about the standards they follow for quality control. A consistent approach leads to fewer defects.

Additionally, consider the testing methods applied. Non-destructive testing ensures that any flaws or weaknesses are detected without damaging the product. This is essential for long-term safety and reliability. Ask for reports detailing the testing results. Unexpected findings can indicate overlooked issues in the production line.

Maintaining seamless boiler tubes is essential for optimal performance. Regular inspection plays a key role in ensuring longevity. Look for signs of corrosion and wear regularly. Simple visuals can point to deeper issues. A slight discoloration may signal that it's time for a thorough check. Don't wait until performance declines.

Cleaning is another crucial aspect. Dust and debris can accumulate in the tubes over time. A thorough cleaning can prevent blockages. For specific areas, reach for a brush or a clean cloth. Yet, don't overdo it. Gentle techniques tend to be more effective. Pay attention to the joints, as these areas often show wear faster.

Documentation of inspections is often overlooked. Keeping detailed records can help track performance trends. This might reveal patterns or highlight recurring issues. Neglecting this can lead to missed problems. Maintaining awareness is vital in ensuring the efficient function of boiler tubes over their lifespan.

| Dimension | Material | Standard Specification | Application | Maintenance Frequency |

|---|---|---|---|---|

| 1" to 5" OD | Carbon Steel | ASTM A106 | Power Plants | Annual |

| 1" to 4" OD | Alloy Steel | ASTM A335 | Chemical Processing | Semi-Annual |

| 3/4" to 6" OD | Stainless Steel | ASTM A312 | Food Industry | Quarterly |

| 2" to 8" OD | Copper Nickel | ASTM B271 | Marine Applications | Monthly |