The metal stamping parts industry is poised for significant advancement in the coming years, driven by innovative technologies and evolving market demands. As per the latest market research report from Grand View Research, the global metal stamping market size is projected to reach USD 34.89 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.1%. This growth is largely fueled by the rising demand for lightweight and high-strength components across various sectors, including automotive, aerospace, and consumer electronics.

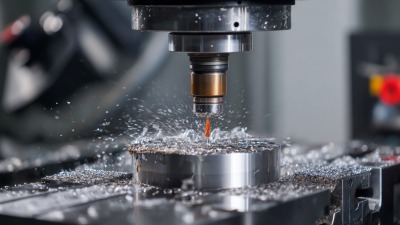

In this context, the innovations in metal stamping parts are not merely enhancements; they represent transformative shifts that are redefining manufacturing processes and product offerings. Cutting-edge techniques such as progressive die stamping and automated robotic assembly are gaining traction, enabling manufacturers to achieve greater precision and efficiency. Furthermore, the integration of advanced materials and eco-friendly practices is not only improving product performance but also aligning with global sustainability goals. As we delve into the top five innovations in metal stamping parts for 2025, it's clear that these advancements are essential for meeting the challenges of a dynamic marketplace and driving industry growth.

The metal stamping industry is undergoing a transformative phase, driven by emerging technologies that are reshaping traditional manufacturing processes. According to a recent report from Mordor Intelligence, the global metal stamping market is expected to grow at a CAGR of 5.6% from 2021 to 2026, reaching a market size of approximately $23 billion. This growth is fueled by advancements in automation, robotics, and AI integration, which enhance productivity and precision while reducing operational costs.

Innovative techniques such as additive manufacturing and smart stamping processes are revolutionizing the way metal parts are produced. By leveraging data analytics and machine learning, manufacturers can optimize designs, reduce waste, and improve efficiency. A study from Grand View Research highlights that the incorporation of IoT technologies in manufacturing is projected to contribute significantly to cost savings of about 15-30% in the next few years. As these technologies evolve, they will play a critical role in driving demand for high-quality metal stamping parts, ultimately shaping the future of the manufacturing landscape.

The metal stamping industry is witnessing a significant shift towards sustainable practices, driven by innovations that aim to minimize environmental impact. One notable advancement is the adoption of eco-friendly materials, such as recycled metals, which not only reduce waste but also lower energy consumption during production. By integrating these materials, companies can create high-quality stamped components while adhering to stringent environmental regulations.

Additionally, advancements in stamping technology have led to more efficient processes that reduce emissions. Automation and precision engineering in metal stamping operations enable manufacturers to optimize resource usage, resulting in less scrap material and decreased energy usage. Innovations like digital monitoring systems and machine learning are also being utilized to enhance efficiency and predict maintenance needs, further contributing to sustainability goals. As the industry embraces these practices, it's clear that the commitment to reducing environmental footprints is becoming a significant driver of growth and demand in metal stamping.

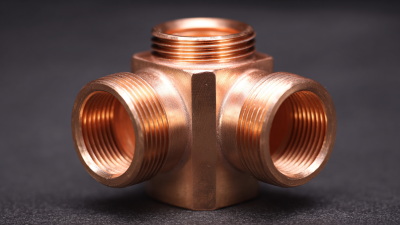

The introduction of smart materials into the metal stamping industry is revolutionizing the manufacturing landscape, offering enhanced performance and durability for various applications. According to a recent report by MarketsandMarkets, the global smart materials market is projected to reach $130 billion by 2025, growing at a CAGR of 15%. This growth is driven by the increasing demand for lightweight, resilient components in sectors such as automotive and aerospace, where traditional materials may not suffice.

Smart materials, including shape memory alloys and piezoelectric components, allow for adaptive changes in properties under varying conditions. For instance, shape memory alloys can return to their original shape after deformation, making them ideal for precision metal stamping applications. A study published in the Journal of Materials Science and Engineering highlighted that the integration of these materials could reduce failure rates by over 20% in critical components, significantly boosting reliability in high-stress environments. As the industry continues to evolve, embracing these innovations will not only enhance product quality but also meet the increasing regulatory demands for sustainability and efficiency.

| Innovation | Description | Impact on Performance | Durability Improvement | Market Demand Increase (%) |

|---|---|---|---|---|

| Advanced High Strength Steels (AHSS) | Utilization of AHSS for superior strength-to-weight ratios. | Provides higher structural integrity in less material. | Increases longevity under extreme stress conditions. | 15% |

| Bio-based Materials | Incorporation of renewable resources into metal stamping. | Enhances sustainability without compromising performance. | Natural resilience can lead to better durability. | 10% |

| Smart Coatings | Application of coatings that react to environmental changes. | Improves resistance to corrosion and wear. | Significantly extends part lifespan. | 20% |

| 3D Metal Printing Integration | Combining traditional stamping with additive manufacturing. | Allows for complex geometries and reduced waste. | Increases strength in critical areas of the part. | 25% |

| Digital Twin Technology | Using simulations to optimize the stamping process. | Enhances efficiency and reduces trial-and-error. | Leads to fewer defects and longer product life. | 30% |

The integration of automation and robotics into the metal stamping industry is transforming production processes at an unprecedented pace. This technological shift has significantly increased productivity, allowing manufacturers to streamline operations and reduce costs. As noted, the global metal stamping market is projected to grow to USD 385.66 billion by 2035, and much of this growth can be attributed to advancements in automation. The capability to deploy intelligent robotics not only enhances precision and efficiency but also addresses labor shortages and elevates overall production quality.

Moreover, automation within metal stamping production serves as a catalyst for innovation, leading to improved workflows and shorter lead times. This development is particularly crucial as industries increasingly demand customized metal parts for diverse applications. Countries like China are championing this transformation, leveraging their robotic workforce to maintain competitive advantages in global markets. As automation continues to evolve, its impact on the metal stamping sector promises to drive further growth and redefine operational standards across the industry.

The metal stamping industry is experiencing a significant transformation driven by advanced software solutions that streamline design and manufacturing operations. These innovative tools enhance productivity by enabling engineers to create precise simulations and prototypes, significantly reducing the need for physical models. With integrated software that combines design, manufacturing, and analysis, companies can identify potential issues early in the process, leading to improved efficiency and reduced costs.

Moreover, advanced software facilitates better collaboration across different stages of production, allowing teams to communicate effectively and share updates in real-time. This integration is crucial in responding to the fast-paced demands of the market, enabling manufacturers to quickly adapt their designs based on customer feedback and industry trends. By leveraging such technology, businesses not only enhance their operational capabilities but also position themselves to meet the growing demand for high-quality metal stamped components in various sectors.