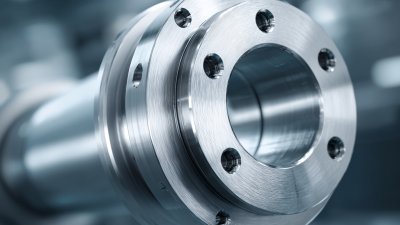

In recent years, the manufacturing and construction industries have increasingly recognized the advantages of using a Chinese Threaded Flange in various projects. According to a report from Global Market Insights, the global flange market is projected to grow substantially, driven by the expanding construction and oil and gas sectors. The Chinese Threaded Flange, specifically, has garnered attention due to its cost-effectiveness and reliability, meeting the stringent quality standards demanded by industry professionals.

Industry expert Dr. Li Wei, a leading authority in flange manufacturing, states, "The precision and durability of a Chinese Threaded Flange make it an ideal choice for projects looking to enhance their performance while reducing costs." This assertion highlights a growing trend among engineers and project managers who are seeking innovative solutions to improve structural integrity without compromising on quality.

As we delve into the top five reasons to choose the Chinese Threaded Flange for your projects, it becomes clear that adopting this versatile component can not only streamline operations but also contribute to sustainable development practices in various sectors. Recognizing these benefits can empower decision-makers to make informed choices that align with their project goals and budget constraints.

In industrial applications, the use of Chinese threaded flanges has gained considerable traction due to their unique advantages. According to a report by MarketsandMarkets, the global flange market is projected to reach USD 23 billion by 2025, driven by the increasing demand for efficient and durable fastening solutions. Chinese threaded flanges, often characterized by their superior manufacturing processes and cost-effectiveness, can significantly contribute to project success without compromising quality.

One of the standout benefits of these flanges is their ability to reduce installation time. The design allows for quick assembly and disassembly, which is pivotal in industries such as oil and gas, where time is money. Furthermore, a study from Research and Markets indicates that the steel flange segment is anticipated to grow at a CAGR of 5.1% from 2020 to 2025, underlining the rising preference for steel threaded flanges manufactured in China due to their strength and reliability.

Tips: When selecting threaded flanges for your projects, always consider the material compatibility and environmental conditions they will be used in. This ensures longevity and reduces maintenance costs. Additionally, leveraging the latest manufacturing technologies can further enhance the performance of flanges, making them an even more valuable investment for industrial applications.

When it comes to budget considerations, Chinese threaded flanges stand out as a highly cost-effective choice for various projects. These flanges are often produced in a more affordable manufacturing environment, enabling suppliers to offer competitive prices without compromising on quality. The streamlined production processes and economies of scale in China significantly reduce operational costs, allowing customers to source high-quality threaded flanges at a fraction of the price compared to other regions.

Moreover, the versatility and durability of Chinese threaded flanges make them a practical choice for diverse applications. Their robust construction ensures reliability under various conditions, reducing the need for frequent replacements and maintenance. Consequently, businesses can achieve substantial savings over the long term. By investing in Chinese threaded flanges, project managers can not only meet their budgetary constraints but also secure reliable components that contribute to overall project efficiency and success.

| Reason | Description | Cost Comparison (%) | Durability (Years) |

|---|---|---|---|

| Affordable Pricing | Chinese threaded flanges offer competitive pricing compared to those produced in Western countries. | 20-30% | 10-15 |

| Bulk Purchase Discounts | Many manufacturers provide significant discounts for bulk orders, reducing overall project costs. | 10-25% | 15-20 |

| Reduced Import Tariffs | Trade agreements have led to lower tariffs for importing Chinese products. | 5-15% | 5-10 |

| Standardization | Chinese threaded flanges adhere to international standards ensuring compatibility across projects. | N/A | 10-25 |

| Wide Availability | These flanges are readily available through numerous suppliers, minimizing lead times. | N/A | 10+ |

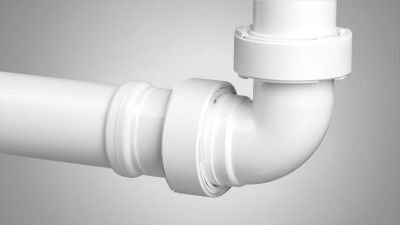

The compatibility and versatility of Chinese threaded flanges make them an ideal choice for various industrial applications. With the increasing demand for efficient and reliable piping systems, Chinese threaded flanges have emerged as a robust solution, compatible with a wide range of materials and fluid types. According to industry reports, the global flange market is expected to grow significantly, driven by the need for reliable connections in sectors such as oil and gas, water treatment, and power generation.

Moreover, the adaptability of these flanges allows them to be used in diverse environments. Recent advancements in flow measurement technologies highlight the importance of integrating versatile components in piping systems. As seen in the latest developments, equipment that provides multi-parameter measurements can significantly benefit from the use of thread flange systems, ensuring seamless compatibility across various setups. By choosing Chinese threaded flanges, project managers can capitalize on their flexibility and precision, ultimately leading to improved operational efficiency.

When considering the use of Chinese threaded flanges in your projects, the quality standards and reliability they meet can significantly impact the overall performance and safety of your installations. Chinese manufacturers comply with international standards such as ASTM, ASME, and ISO, ensuring that their products undergo rigorous testing and quality control measures. This adherence to established benchmarks guarantees that the flanges are manufactured with precision, resulting in smooth threads and a secure fit, which is crucial for high-pressure applications.

Furthermore, the reliability of Chinese threaded flanges is reinforced by modern manufacturing technologies and materials used in their production. Many companies employ advanced techniques such as CNC machining and real-time quality monitoring, which minimize defects and enhance the overall durability of the flanges. As a result, these components can withstand harsh operating conditions, reducing the likelihood of leaks or failures over time. The combination of strict quality standards and innovative manufacturing practices makes Chinese threaded flanges a dependable choice for engineers and project managers looking to ensure the longevity and safety of their systems.

When it comes to selecting the right components for your projects, Chinese threaded flanges stand out for their robust customization options. These flanges can be tailored to meet specific project requirements, offering various sizes, materials, and thread types. This flexibility ensures that engineers and designers can find the perfect fit for their applications, whether it's for industrial machinery, piping systems, or construction projects.

Moreover, the ability to customize Chinese threaded flanges extends beyond mere dimensions. Additional features such as surface finishes, coatings, and pressure ratings can also be adjusted to enhance performance and durability. This level of customization not only improves functionality but also allows for better integration into unique project specifications. By opting for these versatile flanges, businesses can streamline their operations and achieve a higher quality end product, leading to improved efficiency and satisfaction in their projects.