Wear resistant steel plays a crucial role in various heavy-duty applications, from mining machinery to construction equipment. As the demand for durability and longevity in industrial tools increases, manufacturers are turning to advanced materials to withstand the harshest environments. John Smith, a leading expert in the field of metallurgy, emphasizes the importance of this material, stating, "In industries where wear and tear are inevitable, wear resistant steel is not just an option; it is a necessity for ensuring operational efficiency and safety."

The unique properties of wear resistant steel, including its high hardness and toughness, make it an ideal choice for heavy-duty applications. Unlike conventional steel, wear resistant steel is specifically engineered to endure significant abrasion and impact, thus prolonging the lifespan of heavy equipment. This advantage not only results in lower maintenance costs but also enhances productivity in industries like mining, construction, and agriculture. By integrating wear resistant steel into their equipment, companies can achieve greater resilience and performance in challenging work environments.

In conclusion, the importance of wear resistant steel cannot be overstated. As industry demands evolve, the need for materials that can withstand extreme conditions becomes paramount. Experts like John Smith highlight that investing in wear resistant steel is essential for businesses aiming to improve their operational capabilities and reduce downtime.

Wear resistant steel is a specialized material designed to withstand the rigors of heavy-duty applications where abrasion and wear are prevalent. This steel is typically characterized by its high carbon content and unique alloying elements, which contribute to its enhanced hardness and durability. The result is a material that can endure extreme conditions without succumbing to damage, making it indispensable in sectors such as mining, construction, and manufacturing.

The primary attribute of wear resistant steel is its ability to maintain structural integrity despite prolonged exposure to abrasive materials. The microstructure of this steel usually includes a combination of hard phases, such as carbides, which provide superior resistance to wear. Consequently, components made from wear resistant steel tend to have a significantly longer lifespan than those made from traditional steel. Additionally, the toughness of this material allows it to resist impacts and shocks, further extending its usability in demanding environments.

Overall, wear resistant steel is a critical component in applications where performance and longevity are paramount.

Wear resistant steel plays a crucial role in various heavy-duty applications across multiple industries, primarily due to its exceptional hardness and resilience. In the mining sector, for instance, equipment such as excavators, loaders, and shovels frequently encounter abrasive materials. According to a report from the International Journal of Mining Science and Technology, utilizing wear-resistant materials can extend the lifespan of these vital pieces of machinery by up to 50%, significantly reducing downtime and maintenance costs.

In addition to mining, wear resistant steel is essential in the construction industry, where it is utilized in bulldozer blades, buckets, and other heavy equipment. These components are subjected to extreme wear from soil and rock, and studies indicate that wear resistant steel can improve performance and reliability, enhancing productivity on construction sites by as much as 30%. Furthermore, the agricultural sector benefits from employing these materials in tillage and harvesting equipment, ensuring that machinery remains operational for longer periods, especially in challenging farming conditions.

Overall, the integration of wear resistant steel in heavy-duty applications not only promotes equipment durability but also leads to increased efficiency, aligning with the industry's goal of maximizing operational effectiveness while minimizing maintenance disruptions. As industries continue to prioritize productivity, the demand for advanced materials like wear resistant steel will only grow.

Wear resistant steel is a crucial material for industries that operate under high-stress environments. This type of steel is designed to withstand abrasive wear and extreme conditions, making it ideal for heavy-duty applications such as mining, construction, and manufacturing. The primary benefit of using wear resistant steel is its long lifespan, which significantly reduces the frequency of replacements and maintenance costs. By minimizing downtime, businesses can maintain productivity and efficiency in their operations.

In addition to its durability, wear resistant steel is also known for its toughness. This characteristic allows it to absorb impacts without fracturing, an essential feature in environments where machinery is subject to shocks and heavy loads. Companies that invest in this type of steel often see improved performance of their equipment, leading to better overall results. Moreover, using wear resistant steel can enhance safety in high-stress environments, as its reliability can prevent equipment failure that may lead to accidents.

Tips: When selecting wear resistant steel, consider the specific conditions of your application, including temperature and type of wear. Additionally, regular inspections can help identify wear patterns and extend the lifespan of equipment. Lastly, seek advice from experts in metallurgy to choose the best type of wear resistant steel for your particular needs, ensuring optimal performance and cost-effectiveness.

Wear resistant steel plays a crucial role in heavy-duty applications where durability and longevity are paramount. When compared to other material options such as standard carbon steel, aluminum, or even some polymers, wear resistant steel stands out for its superior hardness and toughness. Unlike standard steel, which can succumb to abrasion and wear after extended use, wear resistant steel is engineered specifically to withstand harsh conditions and maintain its integrity under significant stress and impact. This makes it the preferred choice for industries like mining, construction, and manufacturing, where machinery is subject to constant wear.

When considering alternatives, it's important to weigh the benefits of wear resistant steel against other materials. For example, while aluminum is lightweight and resistant to corrosion, it does not provide the same level of hardness, making it unsuitable for high-impact applications. Similarly, although some polymers can resist certain chemicals, they lack the mechanical strength needed to endure abrasive forces.

Tip: When selecting materials for heavy-duty applications, always evaluate the specific conditions the material will face. Consider factors like wear rate, impact resistance, and environmental exposure. Choosing the right material can significantly reduce maintenance costs and extend the lifespan of your equipment.

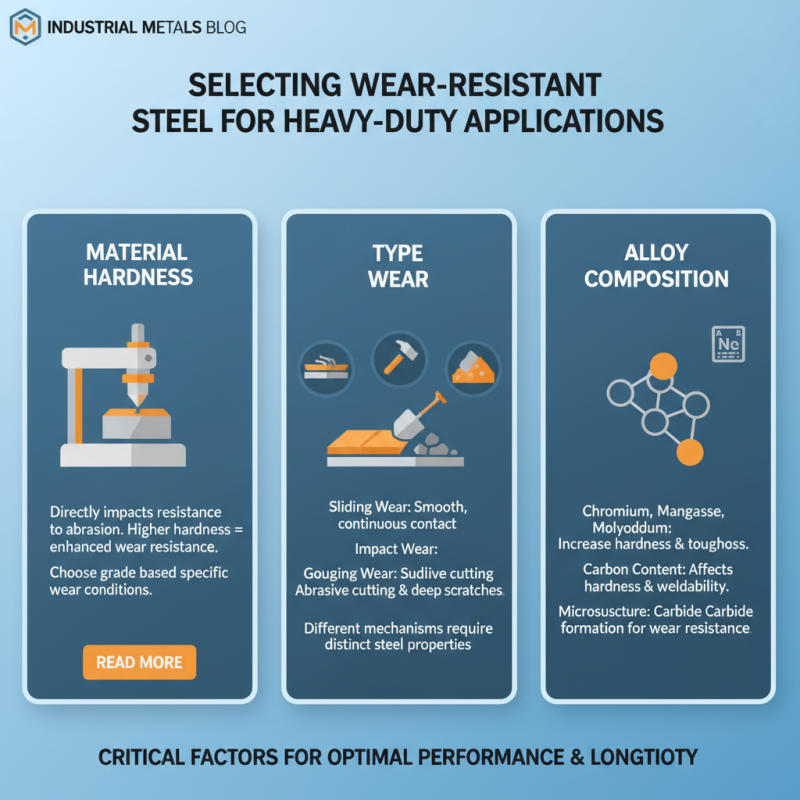

When selecting wear resistant steel for heavy-duty applications, several critical factors must be taken into consideration to ensure optimal performance and longevity. Firstly, one of the primary aspects is the material's hardness, which directly impacts its resistance to abrasion. Higher hardness levels generally indicate enhanced wear resistance, making it crucial to choose a steel grade that will withstand the specific wear conditions of the application. Additionally, understanding the type of wear involved—whether it be sliding, impact, or gouging—will guide the selection process, as different wear mechanisms require distinct properties from the steel.

Another important factor is the thickness of the wear resistant steel. Thicker plates can offer greater longevity and resistance but may also increase weight and affect handling. It's essential to balance these attributes with the project’s requirements, including load-bearing considerations and space constraints. Furthermore, examining the steel's chemical composition can provide insights into its overall performance; elements such as chromium, molybdenum, and carbon play significant roles in enhancing properties like toughness and formability. Properly evaluating these factors will lead to a more informed decision, ultimately ensuring that the wear resistant steel meets the demands of the application while providing cost efficiency in the long run.